views

X

Research source

Using a Tube Cutting Tool

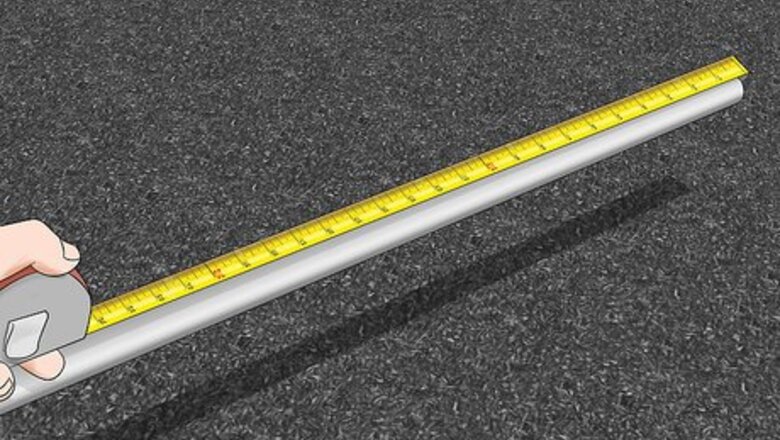

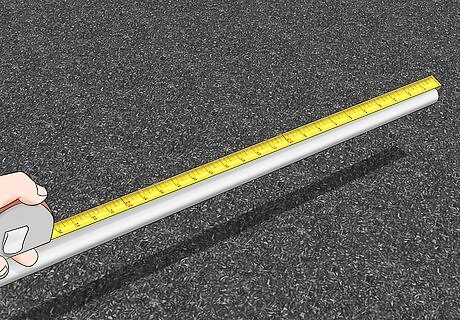

Measure for your cut. Making a precise cut is important when installing new galvanized pipe. For example, if you are planning on threading your pipe, you need to take the length required for adding threads to the ends of the pipe into consideration when marking your cuts. Being precise with your cuts is less important when removing old galvanized pipe. If you are removing pipe and you don't plan on reusing it, just cut wherever it makes removal of that pipe the easiest.

Choose to use a tube cutting tool when cutting new or old pipe. Tube cutters are often used by plumbers for cutting copper and steel pipe they are installing or removing. Tube cutters come in a variety of sizes. Each cutter will typically cut a range of sizes. However, if you need to cut both very small and very large galvanized pipe, then you may need several tube cutters. These are specialized tools that are only designed to cut a pipe, so if you buy one you won't be using it for any other purpose.

Rotate the tube cutter around the pipe. Tube cutters typically have two rollers and a cutting wheel. These three points are rotated around the pipe by turning the handle on the tool. After every few rotations, the tool is tightened so that the cutting wheel cuts deeper into the pipe. While a tube cutter is a hand tool with no motor, it is easy to use and much more efficient than other hand tools used to cut pipes.

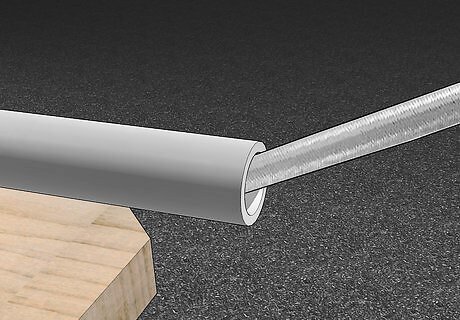

Ream the pipe after cutting to remove burrs. When you cut galvanized pipe with a pipe cutter a burr of steel will be created on the inside edge of the pipe. To get rid of this, you can file the entire inside edge with a rounded file or you can also use a specialized tool that is made to remove these burrs, which is called a reamer. Pipe reamers are available at most home improvement and hardware stores. Alternatively, you can use coarse sandpaper to remove burrs.

Using a Reciprocating Saw or Angle Grinder

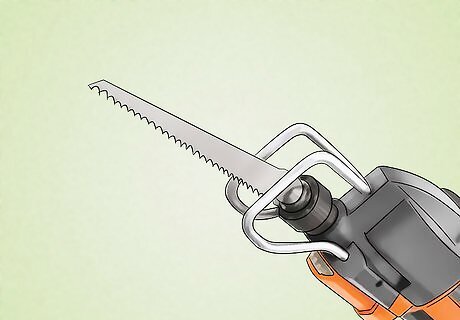

Choose to use a reciprocating saw or angle grinder in tight spaces. There are several power tools that are great for cutting galvanized pipe that is located in tight spaces. If you are trying to remove a piece of galvanized pipe from a tight space, you can either use a reciprocating saw or angle grinder, depending on the space you are working in and the tool you have available. The choice between using an angle grinder and a reciprocating saw depends largely on what you have available. They can typically be used interchangeably.

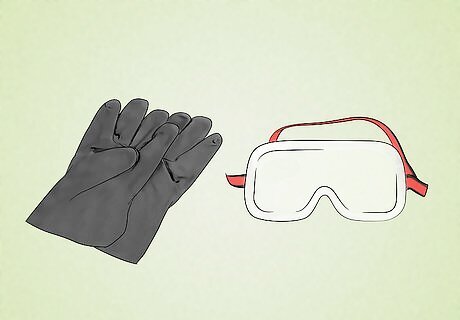

Put on personal protective equipment. When cutting through steel pipe with a power tool it is important to protect yourself from hazards. Put on safety glasses to protect your eyes from flying pieces of steel. Wear gloves to protect your hands from the heat of the pipe (produced by the grinder) in addition to a slipping saw blade or sharp pipe edge. An additional piece of protective equipment you may want to consider using is ear plugs. These can protect your ears from loud noises made during sawing. It is also a good idea to wear long sleeves and long pants to protect your skin from any bits of metal that might fly around while cutting.

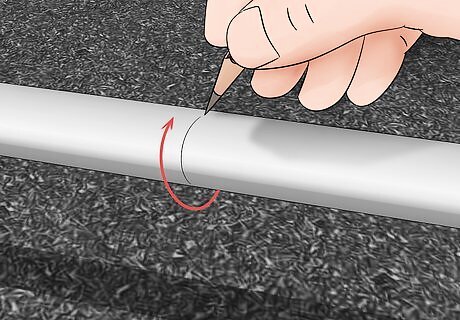

Mark for your cut around the pipe. When cutting a round piece of pipe, it's a good idea to mark the correct length around the whole circumference of the pipe. This will allow you to keep your cut straight as you go. To mark the whole circumference, mark your measurement at several points around the pipe. Then you can connect the marks to make a solid marking around the whole pipe. Marking the entire circumference of the pipe is especially important when using a saw or angle grinder to cut your pipe. It will allow you to keep your cuts straight. Other types of cutting, such as using a tube cutter, will inherently keep the cut straight.

Make sure that the saw or grinder has a metal cutting blade or wheel on it. When cutting galvanized pipe it is important to use the right kind of blade of wheel. A blade for cutting a different material, such as wood, will not work well for cutting through galvanized pipe. Blades that are made to cut through metal tend to have smaller tines than blades made to cut wood.

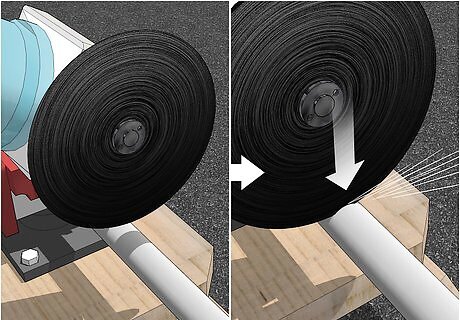

Start power saws or grinders before they are touching the pipe. When you go in to start cutting, the blade of your power saw or grinder should not be touching the surface of the pipe. If it is, the blade or cutting disc can snag on the pipe and make controlling the tool difficult. It can also damage your cutting disc or blade. Instead, hold the blade or disc just slightly off the surface and turn on the tool. This will allow the tool to come up to speed before contacting the surface it is cutting.

Using a Hacksaw

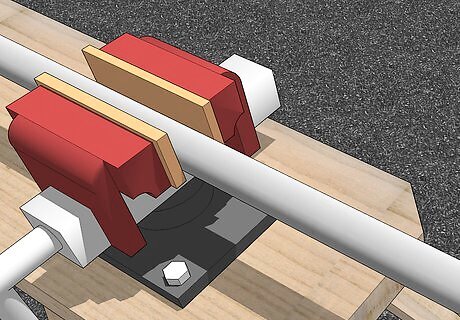

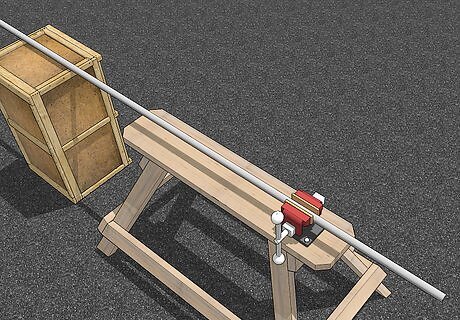

Secure the pipe. In order to cut a pipe successfully with a hacksaw, you need to secure it so it doesn't move while it is being cut. This can be done by having someone else hold it, by placing it in a vise, or by clamping it to a workbench. If you are cutting a piece of galvanized pipe that is already installed, such as when removing old galvanized water pipes, you still need to make sure that the pipe is secure. Make sure it is strapped down or held tightly before cutting so that it doesn't shake uncontrollably when being cut.

Support long pieces of pipe. If you are cutting a long piece of new pipe, you should have the longer end supported. This will make holding the pipe still while you are cutting it easier and it will stop the pipe pieces from falling once the pipe is cut. Wrap a pipe strap around the pipe and screw the other end into a secure overhead joist or beam. For example, if you are cutting a short piece off the end of a long pipe you will need to support the longer end while you make the cut.

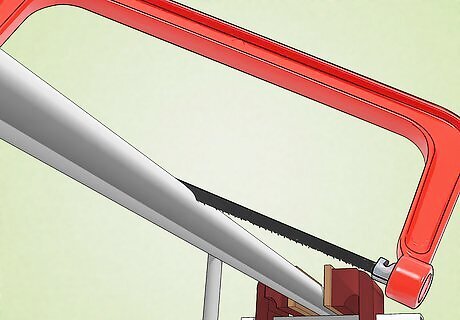

Cut the pipe with a hacksaw. If you do not have a motorized saw and you need to cut a piece of galvanized pipe, you can use a hacksaw. This tool will take a bit of time and effort to use, but it will get the job done eventually. A hack saw works better for cutting steel than other types of hand saws because it typically has small teeth that are designed for cutting metal. These teeth can gradually remove the hard steel as you push and pull them. A hand saw with large teeth designed for cutting wood would not work well for cutting galvanized pipe.

Use gentle pressure and let the tool do the work. When cutting through galvanized pipe with a saw or grinder you should let the tool do the work. There is no need to apply a ton of pressure, as this can hurt your hands and use up a lot of energy needlessly. Instead, be patient and let the tool gradually cut through the steel. Using too much pressure can also create a dangerous situation once you have cut through the pipe with a saw. With moderate pressure, you have control over the saw and you can avoid letting it slip or fall when the cut is done. If you are pushing too hard, the saw could continue moving and cut into something else.

File the cut edge. Once the pipe is cut you will need to clean up the cut. When cutting with a hacksaw you will leave a lot of burrs of metal on the pipe. Get rid of them by using a metal file around the cut, making extra sure to clean up burrs that have developed on the inside edge of the cut. You can also use a reamer or coarse sandpaper to clean up the burrs on the edge of the cut. EXPERT TIP Greg Jeiranyan Greg Jeiranyan Licensed Plumber Greg Jeiranyan is a Licensed Plumber based in Los Angeles, California. With over 10 years of professional experience, Greg and his team specialize in residential and commercial plumbing service calls. His company, Plumbing Geeks, is rated 5 stars on Yelp and is a family-owned and operated plumbing company. Plumbing Geeks has been serving Los Angeles and its surrounding areas since 2021. Greg Jeiranyan Greg Jeiranyan Licensed Plumber Use couplings or unions to prevent corrosion when replacing galvanized pipe. When replacing galvanized pipe sections, either use a G-coupling for direct connections or a dielectric union for connecting to copper to prevent corrosion. You may need to upsize the copper for proper fitting. Or use a coupling with a brass nipple to separate copper from galvanized to reduce corrosion. These techniques maintain and extend the life of older plumbing.

Comments

0 comment