views

Insulating Wires with Heat Shrink Tubing

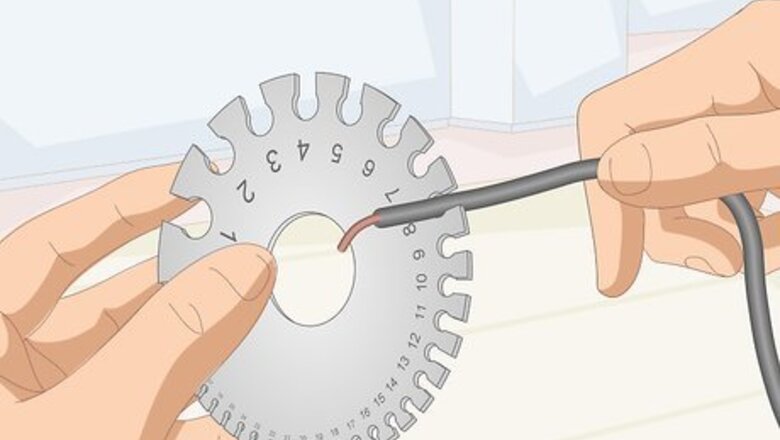

Measure the wire with a wire gauge tool. Feed the wire that you plan on applying heat shrink wrap to into one of the holes on a wire gauge tool to see if it’s a tight fit. If the wire can move around inside the hole on the tool, then try checking the next size down. Once you can feed the wire into a hole and it doesn’t shift around while it’s inserted, then write down the size of the gauge so you know what tubing to buy. You can buy a wire gauge tool from your local hardware store. You don’t need to strip the insulation off of the wire if it already has it since the heat shrink tubing will go around it. If the wire doesn’t fit in the wire gauge tool or has an irregular shape, then you can also use a ruler or tape measure to find the diameter.

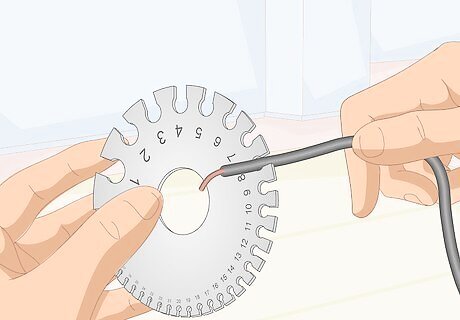

Pick tubing that has a shrunken diameter smaller than the wire you’re insulating. Look on the packaging to find the diameter of the tube before shrinking it as well as the shrink ratio it has, which is usually between 2:1 and 6:1. Divide the diameter of the shrink tubing by the first number in the ratio to find its shrunken diameter. Calculate which tubing will shrink to a size smaller than the diameter of your wire to ensure that it has a tight seal. For example, if the original diameter of the tubing is ⁄2 inch (1.3 cm) and it has a 2:1 shrink ratio, then it will become ⁄4 inch (0.64 cm) once you heat it. If it had a 3:1 ratio, then it would be ⁄6 inch (0.42 cm) after you shrink it. You can buy heat shrink tubing from hardware stores or online. Get heat shrink tubing that matches the color of your wire if you want it to blend in more.Tip: Make sure the tubing has a large enough diameter so you can slide it over any wires or connections to guide it into place.

Cut the tubing ⁄2 in (1.3 cm) longer than the section you’re covering. Measure the length of the wire section that you need to cover with the tubing and then add an additional ⁄2 inch (1.3 cm). The extra length of tubing will cover the insulation on the wire around the area you’re covering to ensure that it makes a tight seal and doesn’t leave any wire exposed. Use a pair of scissors to cut the tubing to size. The heat shrink tubing may also shrink lengthwise by about 5-7% when you heat it, so you can add more to the length if you want to.

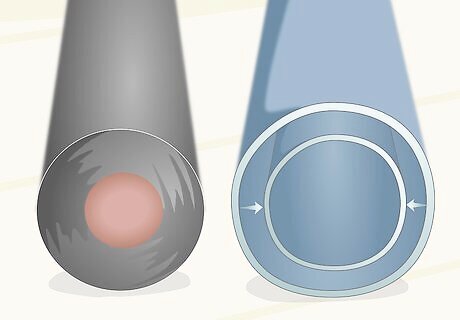

Slide the tubing onto the cable to cover the section you need to insulate. Once you cut the tubing to size, feed the end of the wire through the middle of the tubing. Continue sliding the tubing down the length of wire until you reach the area you’re insulating. Make sure the tube’s positioned so it extends ⁄4 inch (0.64 cm) past the section on each side so the exposed wires are sealed. If you’re covering up a wire splice, position the tubing over the center of the splice so it overlaps both sides equally.

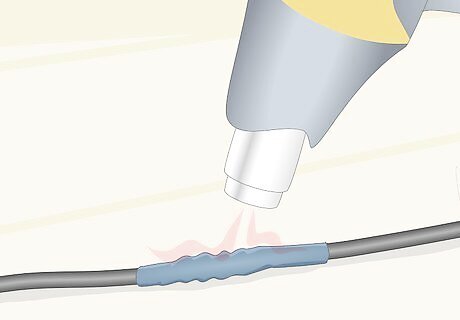

Heat the tubing with a heat gun so it shrinks around the wire. Hold a heat gun about 3–6 inches (7.6–15.2 cm) away from the tubing and turn it on. Move the nozzle of the heat gun back and forth along the length of tubing so it starts to shrink. Rotate the wire so you can heat all sides of the tubing evenly to make sure it shrinks to size and that there are no air bubbles inside. Continue heating the tubing until its tight against the wires underneath it. You can also rub the tubing with the side of a soldering iron to shrink it, but be careful not to heat it too much since you could damage the wires underneath or make the tubing brittle. You may hold the tubing over the open flame of a lighter, but it won’t heat evenly and you may not have a perfect seal. Hair dryers may not be hot enough to make the tubing shrink, but you can try using one on the highest heat setting. The shrinking temperature for the tubing can usually be found on the packaging.

Let the tubing cool completely before you apply any stress to it. Leave the tubing for about 5 minutes so it has a chance to cool around the wire. Once it’s cool to the touch, you can handle and bend the wire into the position you need.

Using Heat Shrink Tubing around the House

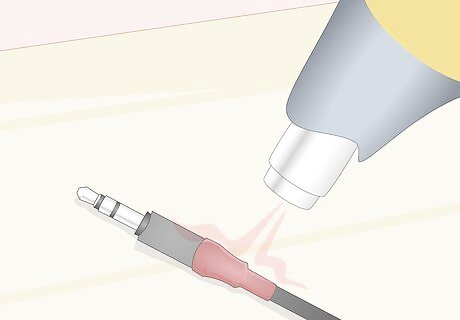

Reinforce a headphone jack so it doesn’t break or bend. Choose heat shrink tubing that has a shrunken diameter that’s slightly smaller than the diameter of your headphone jack. Slide the tubing over the headphone jack so it overlaps where the headphone cord comes out of the base. Heat the tubing over the headphone jack to shrink it in place and make a more rigid connection. Be careful not to melt any of the plastic on the actual headphone wire since you could cause damage to the wires or expose them. Applying heat shrink tubing to a headphone jack that’s already broken won’t fix it.

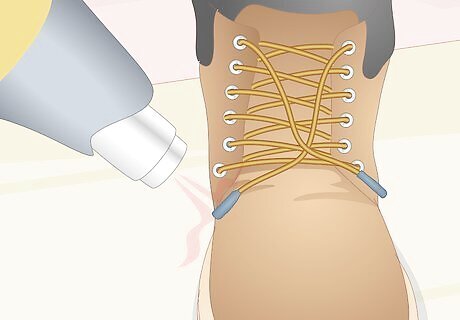

Prevent shoelaces from fraying by sealing the ends in shrink tubing. Aglets, the plastic ends on shoelaces, prevent your shoelaces from falling apart, but they may break off over time. Cut heat shrink tubing so it’s about 1 inch (2.5 cm) long and slide it onto the end of your shoelace. Use a heat gun to shrink the tubing so it holds the end of the laces tight so it doesn’t fray anymore. Use shrink tubing that’s clear or the same color as your shoes so it doesn’t clash.

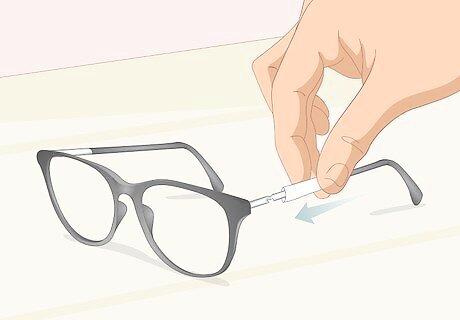

Fix broken glasses frames with heat shrink tubing. If the arm broke off your glasses, slide 1–1 ⁄2 inches (2.5–3.8 cm) of heat shrink tubing onto it. Use tubing that’s the same color as your frames so it blends in well. Hold the broken glasses arm against your frames and guide the tubing over the joint. Use your heat gun to shrink the tubing so the glasses arm stays in place. Be careful heating plastic glasses frames since you could distort their shape if it gets too warm.

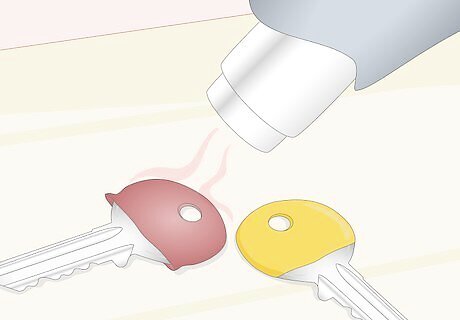

Add heat shrink tubing to keys to identify them easier. Get multiple colors of heat shrink tubing that are large enough to fit over the largest ends of your keys. Slide the tubing over the key and use a heat gun or another heat source to shrink it. Once the tubing is tight around your key, use a small screwdriver to poke a hole through in the tubing so you can still put the key on a ring. Use a different color for each key so you can easily find the one you need quickly. Putting heat shrink tubing on your keys also prevents them from making a lot of noise when you pick them up or set them down.

Put heat shrink tubing on tool handles so you can get a better grip on them. If you have tools in your toolbox that don’t have a plastic grip, you can easily add one with heat shrink tubing. Get tubing that has a shrunken diameter that’s smaller than the diameter of the tool’s handle and cut it to size with a pair of scissors. Metal tools may get hot as you heat up the tubing, so wear work gloves while you’re applying the handle.Tip: Label the heat shrink tubing with the size of the tool so you can see it easily from a distance. That way, you can avoid sifting through your tools to find the right size.

Comments

0 comment