views

Putting Screens Back in Place

Pay attention when you take the screens out. Some screens only go back in one way, and if you don't put them back in the same way, they aren't going to stay. Look at the screen when you're pulling it out, and mark the top of the screen if you need to. If you forgot to look at the screen when you took it down, pull out another one to see how it goes in place. The spline will always face outward.

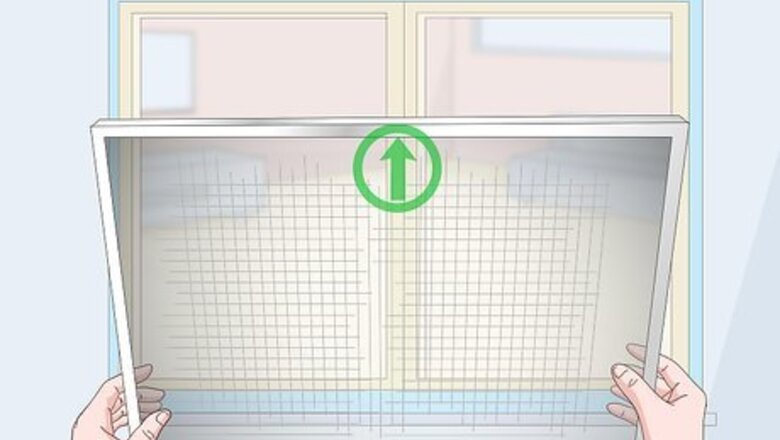

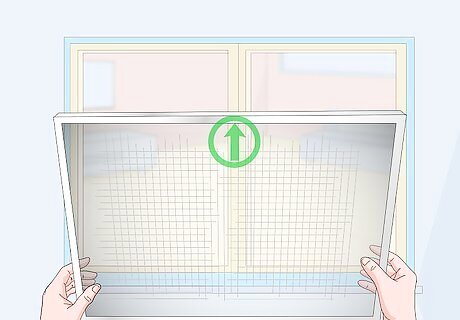

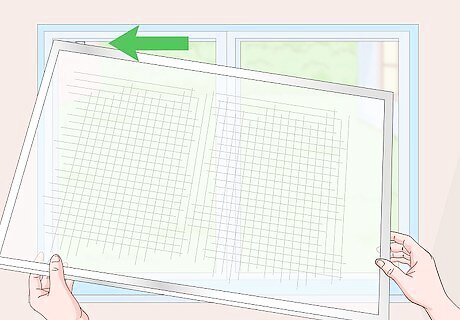

Start from the top. It's usually easiest to begin from the top of the window and work your way down. However, as you slide it into place, make sure the pressure clips are falling into the proper track on the right. Most often, the springs should go to the right when looking at the window from the outside.

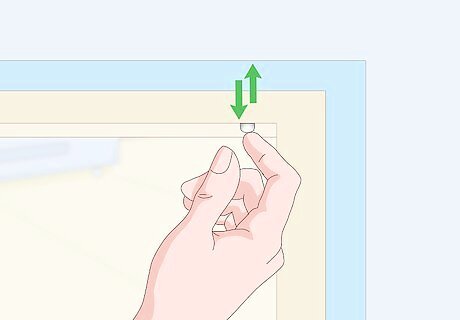

Check the springs or pressure clips if it won't go in. These springs look like little metal strips that create a curve on one edge. Sometimes, the clips pop out of place. They should be against the outside edge only, not flopping to the left or right.

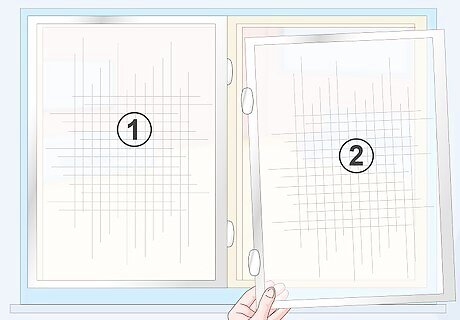

Place 2-part screens in like a puzzle. The top screen will have a lip at the bottom that goes over the bottom screen. The pressure clips, if the screen has them, need to be to the right when looking at the window from the outside. Press the pressure clips into the track on the right, then press in the left top corner. Push the screen to the top without pressing in the bottom left corner. Insert the second screen under the top screen's bottom lip with the pressure clips facing right. Push the screen all the way over to the right. Press the bottom left corner in, while still keeping the top screen's bottom corner and the bottom screen's top corner out a bit. Once the bottom left corner is in, press on the left middle part where the corners meet to set it in place.

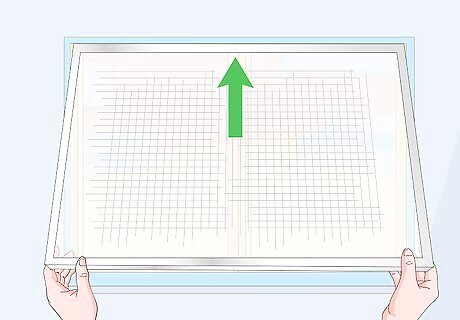

Set in a 1-part screen with the springs to the left from the inside. If you need to put the screen in from the inside, the springs should be on the left. The feathered/pleated edge will go on the top. Slide the top part of the screen out the window, and bring it back flat against the window. Set the screen in the tracks with the springs in place. Lift the screen up the window, and set it in place from the top if you can. To set it in place from the top, press in towards the house at the top corners. You can do this from the outside, or if your house has windows that open from the top and bottom, from the inside.

Replacing a Metal or Vinyl Frame Screen

Purchase the materials you'll need. You can buy spline (the rubber seal), a spline rolling tool, and screen at any hardware store. Typically, you can only by screen in big rolls, which you'll then cut down to size. Fiberglass screen will give you a chance to start over if you mess up. Aluminum will hold up to more, but it tends to take on the shape of whatever you're doing. That means you won't get a chance to try again if you make a mistake. If you have pets, consider using pet screen, which is meant to hold up to the weight and claws of your pets.

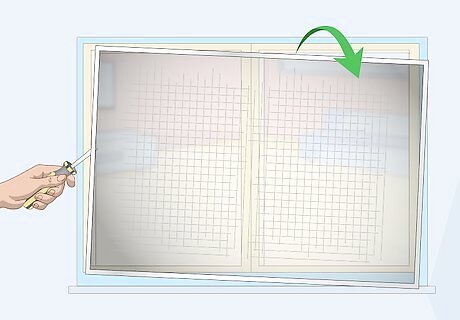

Pop the screen frame out of your window. It should come out easily. If it doesn't, use a screwdriver or the back of a hammer to help pry it out. Lay the screen down on a flat surface so you can work on it, preferably a work table that you can screw stabilizers into. If you need to replace the frame, too, you can buy the sides and corners at a hardware store. Just measure how long the sides need to be, and then pop them together with the corner joints to create the frame. You'll only need to replace the frame if it is bowing severely or rusted out.

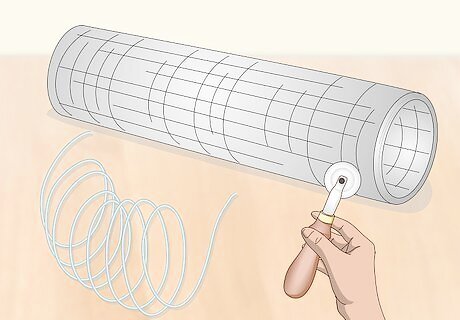

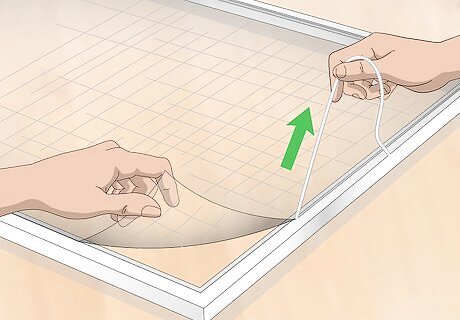

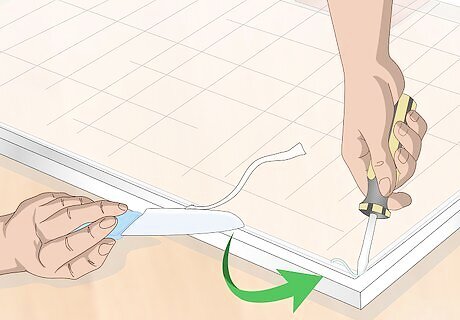

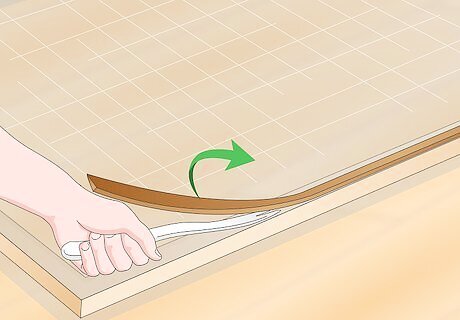

Pull up the rubber spline and take the screen out. The spline is the black rubber seal holding the screen in place. It looks like a black cord, stuffed in the edge of the frame. Use a screwdriver to help pry it up, and then pull it out. Pull up the screen once the spline is out. Grab one edge of the screen and pull it out of the frame. It should come out easily now that the spline is gone. Don't try to reuse the spline. It gets old and brittle after a while. Scan each corner of the frame for a spline end. Once you find the end, slip the screwdriver underneath and pry it up. Slowly pull the entire spline out from around the window frame. The spline may be cut in sections. If this is the case, just repeat the process until the entire spline is out of the window frame grove.

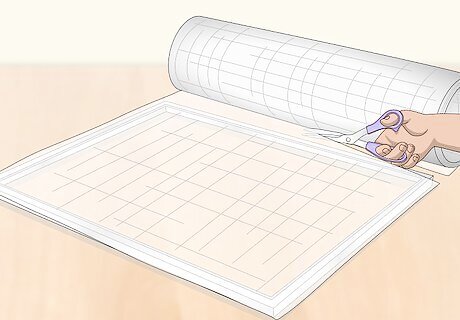

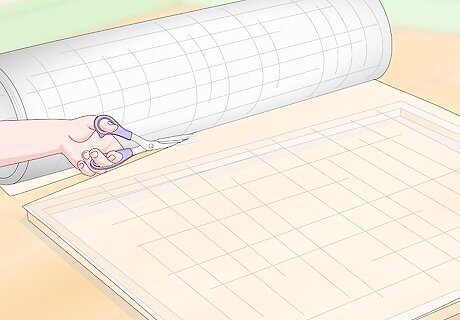

Cut out a section of new screen. Lay the roll of screen over the window frame. Cut the screen so you have 2 inches (5.1 cm) or so of excess on each side. The extra screen gives you room for mistakes. Plus, the spline will take up part of the screen.

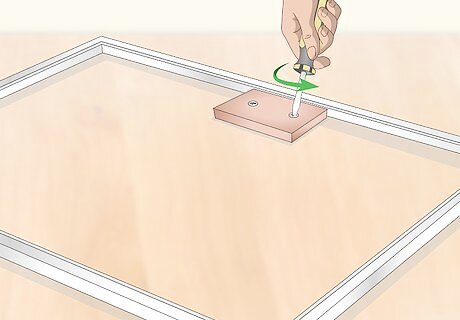

Use stop blocks to hold the frame in place. Screw a piece of wood to your work table on the inside of the frame along the long side. The piece of wood can just be a scrap you have lying around that's at least 2 to 3 inches (5.1 to 7.6 cm) long. You're just using it to brace the frame; don't screw it into the frame. Pull the long side taut against it, and screw in another wooden piece across from it along the other long side. These pieces will keep the frame from bowing in as you work. While this step isn't absolutely necessary, it does help the frame keep its shape.

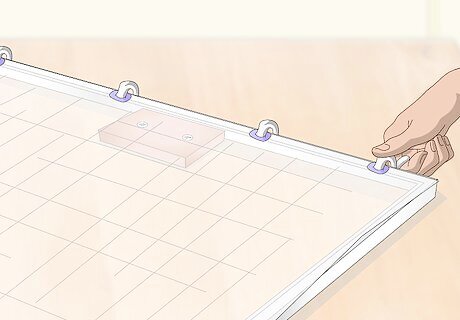

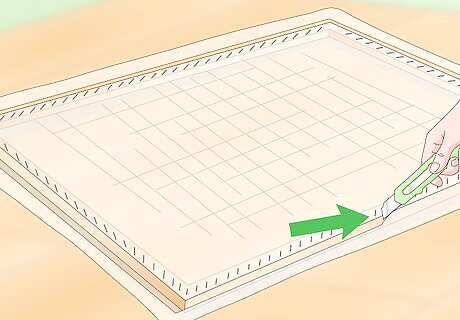

Place 2-4 clamps on one long side of the screen. The clamps hold the screen in place against the frame. In addition, they ensure that when you are rolling in the spline on the other side of the screen, the screen will remain taut. Use enough clamps to hold the screen in place.

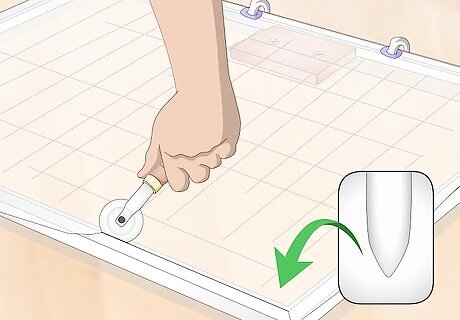

Press the screen into place along the opposite side with the roller tool. Using the convex end of the roller tool, run it over the screen on the side opposite the clamps. Push the tool and screen into the frame's groove. Just do one of the long sides for now. After you roll the screen in, look down the screen. Make sure that there are no bubbles in the screen. If bubbles are present, remove the screen and roll it back in, ensuring you don't have any bubbles this time. Work from corner to corner. If your screen has lift tabs, small plastic handles to help remove the screen, place them in the track before you pre-roll the screen. You want these tabs to be on the opposite side of the spline, so that when the screen is put back into the window, the pull tabs will be on the inside of the house.

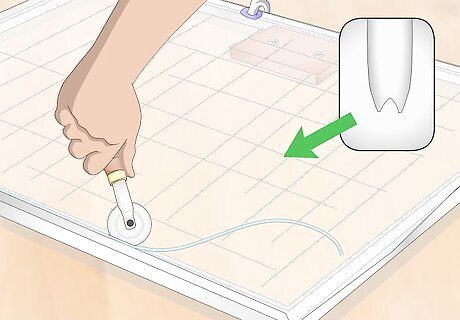

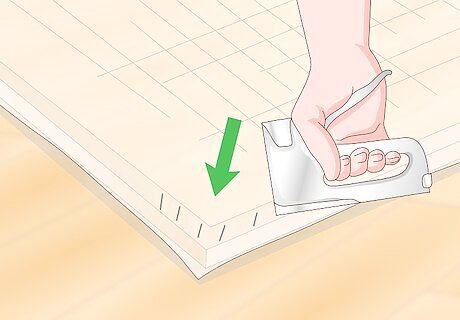

Use the concave side of the roller tool to press the spline into the frame. Lay the spline on top of the frame track where you just pressed the screen in. Press the roller tool over the spline, and run it along the edge, pushing the spline seal into place. Rolling the spline in may take several passes but make sure at the end that the screen is all at the same depth in the track. Take your time with this step. If you go to fast or push too hard, the screen may rip on the inside of the frame and then you have to start all over. Screening is a slow patient process; take your time and do it right the first time.

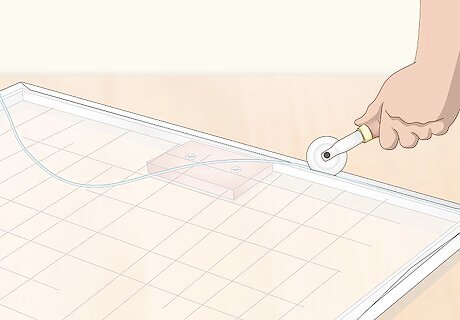

Do the opposite edge the same way. Take the clamps off the screen. Stretch the screen over the frame so it's taut, and then press the screen into the frame's groove with the roller tool. Apply the spline, and press it in as well, using the other side of the roller tool. If you're using fiberglass screen and you mess up, you can pull it out and do it again. If you're using aluminum, you'll have to cut new screen if you make a mistake.

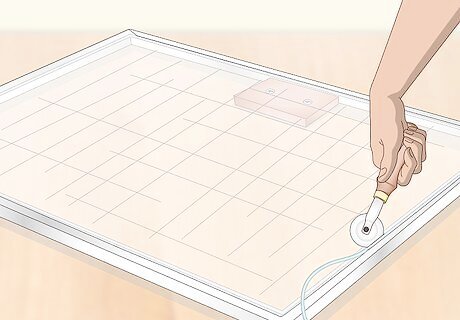

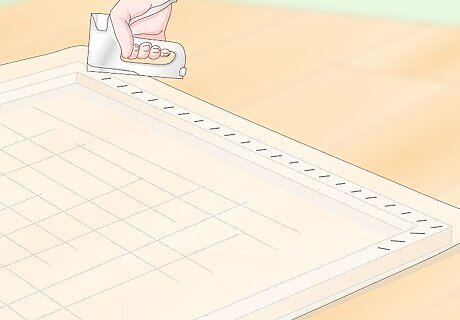

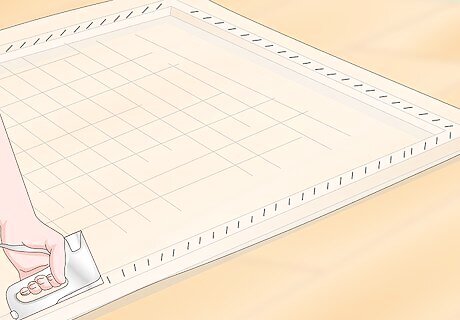

Repeat the process for the other 2 edges. Pull the screen tight over the frame on one edge, and roll it into place. Roll the spline into place, too. Do the same on the other side, avoiding wrinkles as you go by pulling it as tight as you can.

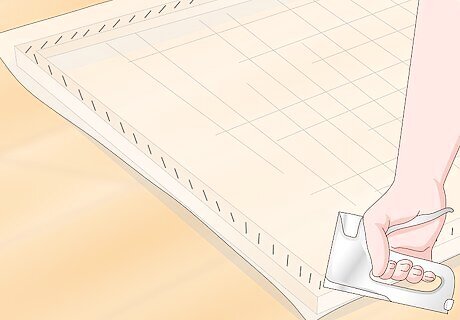

Slice off the excess screen and press the spline into the corners. Cut off any excess spline first. Lay the knife flat on the top of the spline, and direct the blade towards the frame.Cut along that edge to trim off the excess screen. With a screwdriver, tuck the spline in at the corners if it's sticking up. Just press down with a screwdriver so the spline will stay nicely in place. Make sure you use a sharp blade, as a dull one will just drag the screen along, not cut it.

Changing the Screen in a Wood Frame

Remove the wooden window frame from the window, if possible. Removing the screen and working on a flat surface will be much easier than attempting to work with the screen while it is still in the window.

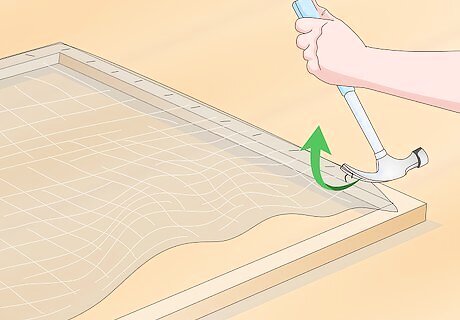

Pry the molding out of the window that's holding the screen in place. Use a thin pry bar to gently pull up the molding. It's important to be gentle because you want to be able to use the molding again. Tap on the end of the pry bar with a hammer to help work it under the molding. Once you get the molding out, tap the nails on the pointed end and remove them with a hammer.

Take the old screen off the frame. Use the claw side of a hammer or pry bar to pull out the staples or nails that hold the screen in place. As you do, the screen should start to come off the frame. Pull it up, and set it aside to discard it later. If any nails or staples are left in the frame after you remove the screen, pry them out.

Cut a piece of screen to fit the frame. Leave at least 1 to 2 inches (2.5 to 5.1 cm) of extra screen on each side of the frame. It's better to cut more than you need than to have to cut it again because you don't have enough. You should have at least at least 2 sides that meet at a right angle. That will make it easier to attach the screen.

Starting stapling or nailing at one edge of the right angle. Lay the right angle of the screen into a corner, fitting it into the grooves for the screen, and staple it on the short side of the corner. Staple the other side of the corner into place, and start working along that long edge, pulling the screen taut as you go. Add staples or nails every 1 inch (2.5 cm) or so. Make sure the staples are as flat as possible against the frame.

Set the top in place with staples or nails. Go along the short side connected to the right angle. Pull the screen tight as you go across the edge, stapling every 1 inch (2.5 cm) or so.

Staple the opposite long edge in place. Pull the screen taut across the frame. Start stapling from the short edge that's already stapled in place. Make sure the screen is tight going across and down the frame as you staple.

Attach the bottom edge. Stretch the screen as much as you can across the frame, then staple or nail it into the bottom corner. Run staples or nails across the bottom edge. With this step, you should finish stapling the screen into place.

Trim the screen using a utility knife. Run a utility knife along the inside edge of the frame. Try not to cut the wood behind it with the knife. Trim the 2 sides that have excess screen, and discard it. You can trim the screen earlier if it's in the way while you're stapling. You should only have to trim the screen on 2 sides if you used a right angle.

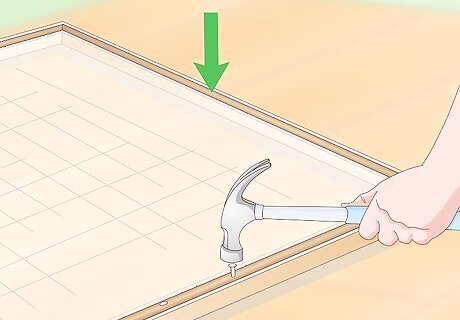

Put the molding back in place. Lay the pieces back down where they belong. Use nails to drive them back into place. Create new holes, or use larger nails in the old holes. If a piece broke, you can glue it back together or buy a new piece of molding.

Comments

0 comment