views

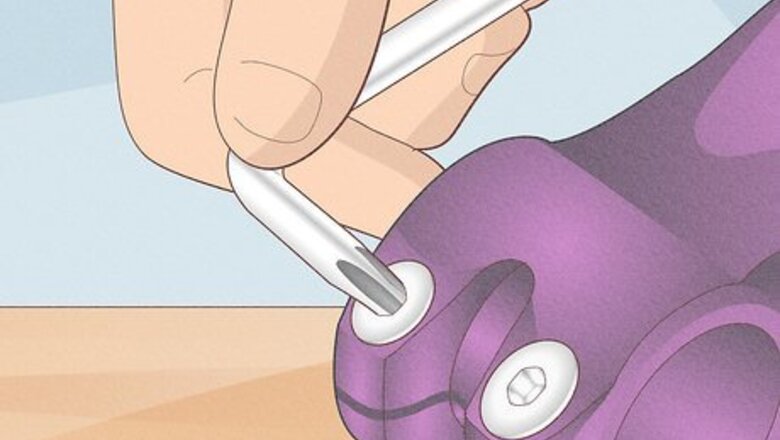

Use a Torx wrench instead.

The star shape of a Torx wrench gets more grip on the screw head. A Torx wrench has a bit shaped like a 6-pointed star, and you probably have one if you have a tool kit at home. Choose a Torx wrench with a bit that’s slightly larger than the hole, and push it in firmly. Then, just turn the wrench counterclockwise to get the stripped allen-head screw out. If you don’t have a Torx wrench, you can buy a set from your local hardware store or online.

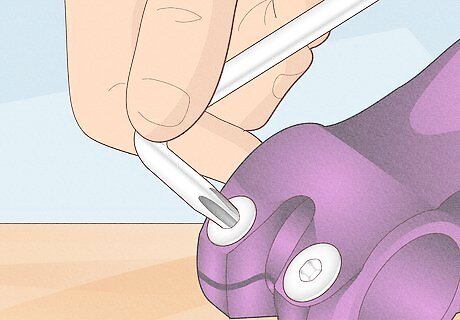

Put a rubber band on the screw head.

A layer of rubber adds a bit more traction to your allen wrench. Try to find a wide rubber band that completely covers the hex hole on the screw. Then, push your allen wrench into the hex hole so it fits firmly. Try unscrewing the bolt or screw as you normally would to see if you get enough grip to remove it. If you don’t have a rubber band, a disposable rubber glove works well in a pinch.

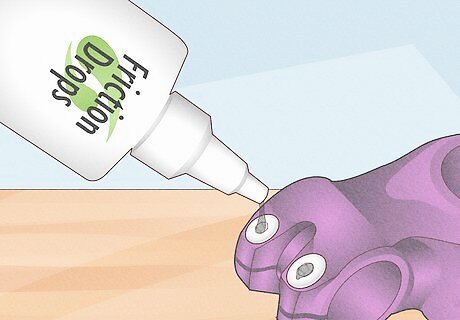

Apply friction drops to your allen wrench.

Friction drops give your allen wrench extra grip if it has a loose fit. Friction drops are made from a solution with fine-grit metal powder that fills in the gaps between your wrench and the stripped hex hole. Put a drop or two of the friction drops inside of the hex hole and push your allen wrench in. Wiggle the allen wrench a few times to help the friction drops catch before unscrewing the screw. You can buy friction drops online or from your local hardware store.

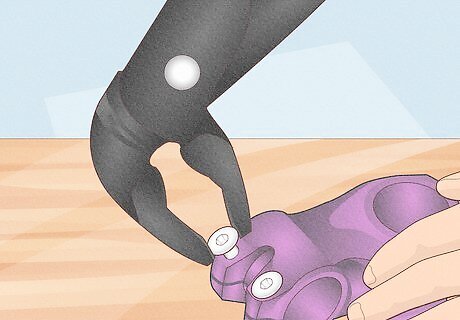

Grip the screw head with channel-lock pliers.

Pliers work best to remove a stripped allen bolt with a raised head. Channel-lock pliers stay secure when you close the jaws so they won't loosen up or slip. Clamp the jaws of the pliers around the top of the screw head. Try to turn the screw or bolt counterclockwise until it loosens up. Channel-lock pliers are in most tool kits, but you can buy them from a hardware store.

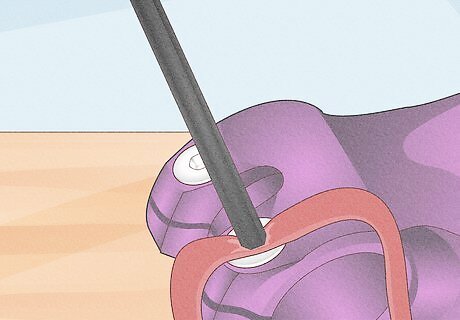

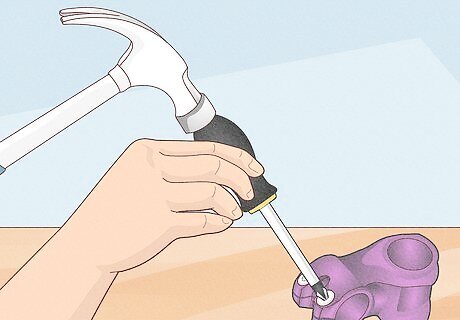

Strike the screw with a hammer and screwdriver.

The shock from the hammer can loosen the screw to get it out. Choose a screwdriver with a bit that fits into the hex hole on the stripped screw or bolt. Start by tapping the bottom of the screwdriver’s handle lightly. Slowly hit with more force to loosen up the screw so it’s easy to remove by hand. Put on a pair of safety glasses in case any pieces of metal break off of the screw. Thin or delicate materials are more likely to break when you hit them, so try out another way to remove the screw or bolt.

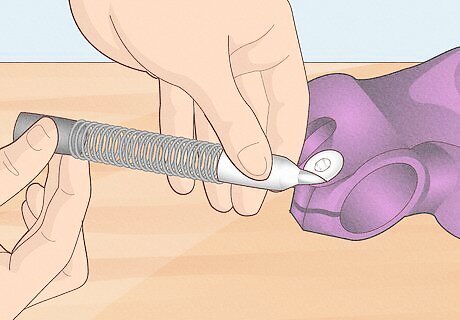

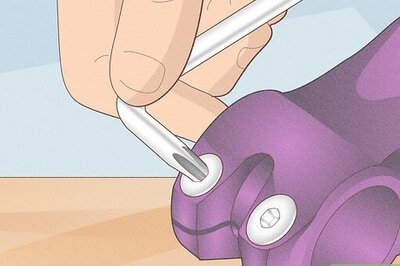

Tap the screw counterclockwise with a center punch.

A center punch can catch on the screw head and help unscrew it. A center punch has a pointed end that’s spring-loaded. Place the bit on a flat part of the screw head so the sharp end of the punch points to the left. Pull up on the center punch’s spring and let go to apply force to the screw. It may take a few tries, but the bit will catch in the screw head so it turns the screw with each hit. If you can’t get the screw to turn just by using the spring, try tapping the back of the punch’s handle with a hammer.

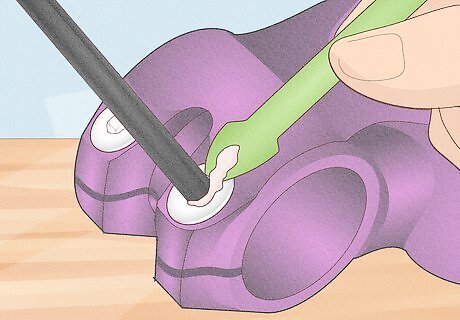

Epoxy an old allen wrench to the bolt.

It's easy to unscrew a stripped allen screw with the wrench attached to it. Use an allen wrench that you don’t mind getting rid of since you won’t be able to remove it. Mix a 2-part epoxy and spread it in the hex hole and onto the end of the allen wrench. Press the allen wrench into the hole and let the epoxy set completely for 1–2 days. Once it’s dry, just turn the allen wrench counterclockwise to remove the screw. You can buy epoxy from your local hardware store. Be careful not to get the epoxy anywhere on the surface around the screw head to make sure it doesn’t get stuck in place.

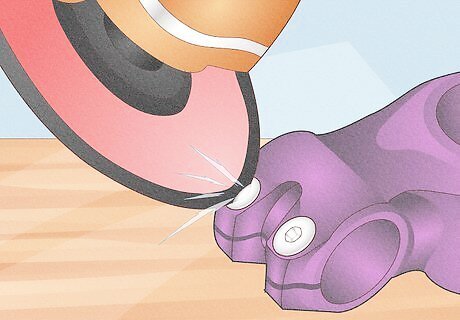

Cut a slot in the screw head with an angle grinder.

A new slot lets you get the screw out with a flathead screwdriver. An angle grinder is a power tool with a rotating circular blade made to cut through metal. Draw a line on the top of the screw head to follow along with and put on a pair of safety glasses. Use your grinder to cut a straight, shallow slot in the top of the screw. Then, just turn a flathead screwdriver counterclockwise in the slot you just cut to get the stripped allen screw out. If you don’t have an angle grinder, you can try hitting a flathead screwdriver with a hammer on the screw head to chisel a new slot.

Try a screw extractor.

Screw extractors fit on your drill and cut through the screw to pull it out. Screw extractors have a cutting drill bit on one end and a removal bit on the other. Put the extractor in your drill with the cutting bit exposed, and drill a shallow hole in the middle of the screw head. Then, flip the extractor over to the removal bit. Place the removal bit in the new hole you just made and set your drill to reverse to unscrew the screw. You can buy a screw extractor kit from your local hardware store for around $10–20 USD. They're reusable, so you can keep one in your toolbox for future use.

Drill the screw out.

Grinding out the old screw with a high-torque drill clears out the hole. Choose a drill bit that’s about the same diameter as the screw’s threads and put it into your drill. Set the drill bit in the hex hole and put on a pair of safety glasses before you start. Apply light downward pressure and use a low and slow speed to drill straight through the screw. When you’re finished, you can easily pull what’s left of the screw out with a pair of needlenose pliers.

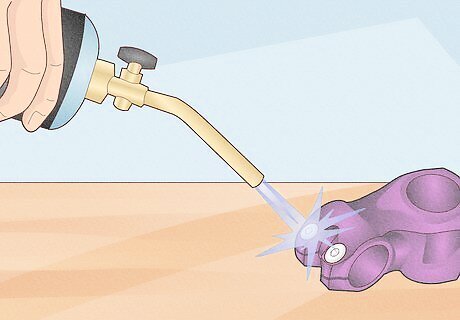

Heat the screw to loosen it.

Heat works best to get a stripped allen screw out of metal. Put on safety glasses and light a butane or propane torch. Hold the tip of the flame over the screw head for 5–10 seconds, but don’t let it get red hot. Put your allen wrench in the hole and try turning the screw or bolt counterclockwise to fully remove it. Avoid using heat to remove screws or bolts from delicate or flammable materials.

Comments

0 comment