views

Removing the Original Molding

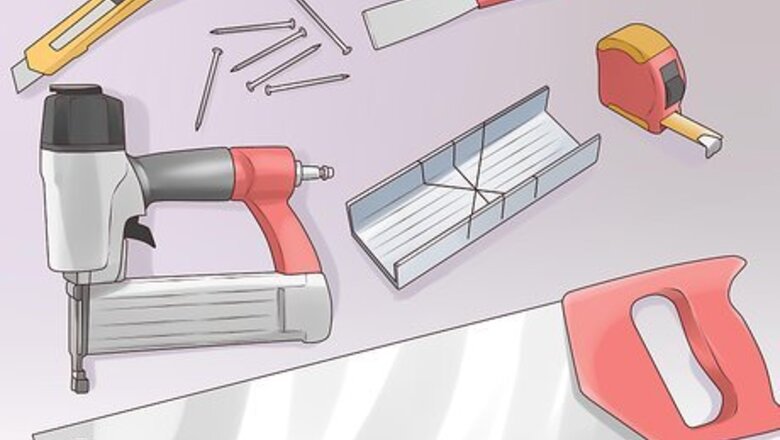

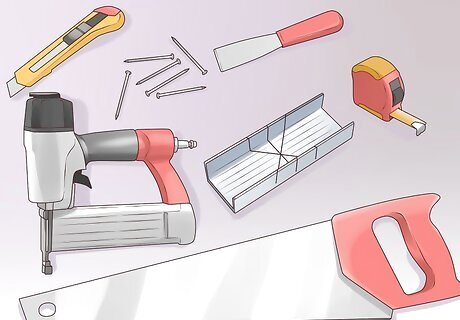

Gather your tools. Before you start doing anything, you'll want to gather the tools you'll need. Thankfully you don't need much! Get a utility knife, a putty knife, a measuring tape, a pneumatic nail gun, nails (long enough to get through your shoe molding and into your baseboards or wall studs), a miter box (or miter or table saw, if you have one), and a saw. You might also want paint, varnish, caulk, a nail setter, and a nail crayon if you want to get the shoe molding looking finished and professional. Some people may need to drill pilot holes for their nails if the molding is very brittle or thin (since some molding may be prone to cracking). If so, you'll need a drill with a bit smaller than the nails you will be using.

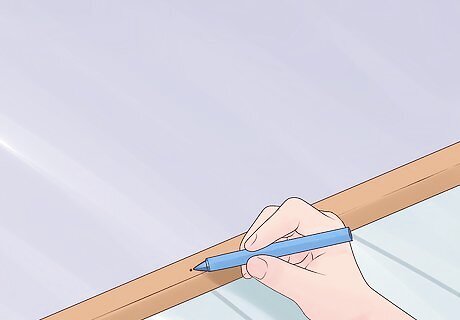

Loosen the molding. If you are removing old base molding, start by taking a utility knife and carefully cut through any paint that is adhering the base molding to the baseboard. This will prevent you from chipping the paint on the baseboard as you pry away the base molding.

Pull away the molding. Using a stiff putty knife, work the base molding loose by pushing it behind and under the base molding. Be careful not to damage the baseboard or the floor. Pry the molding completely away from the baseboard using a flat bar, then remove all the nails.

Prep the wall. While the molding is removed, you have an excellent opportunity to sand and paint your baseboards. If they are in good shape, continue on with the base molding installation.

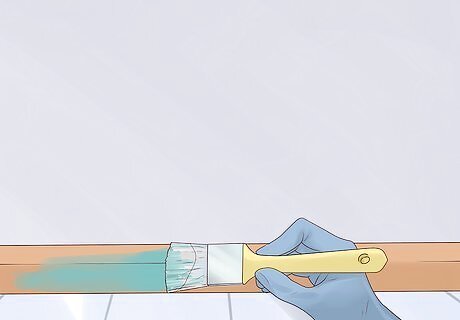

Prep your new molding. Before you cut your moldings to length, you should prep and apply a finish to them. Take your new wood moldings and lightly sand them. Lay them on a set of saw horses and finish them to match your floors. This can be as simple as a few coats of varnish.

Cutting Your Pieces

Measure the room. Measure the area that you will need to cover in shoe molding. Using a tape measure, measure all along the wall. You'll want to write down the exact measurements of each run, from corner to corner. The overall measurements will tell you how much shoe molding to buy and the run measurements will tell you how long to cut each section. If you have any outside corners in your room, you'll want to cut the molding for that section longer than the wall itself. Add about 1-2". This is necessary to make sure that the two pieces will be long enough to go around the whole corner and stay connected. You may have a wall that is longer than an individual piece of shoe molding. Don't worry! We'll show you how to join two pieces together with as little a seam as possible.

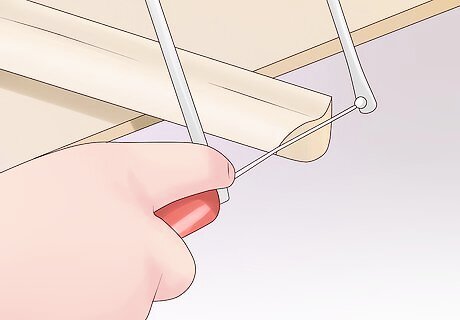

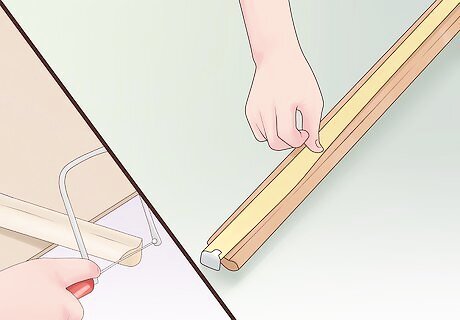

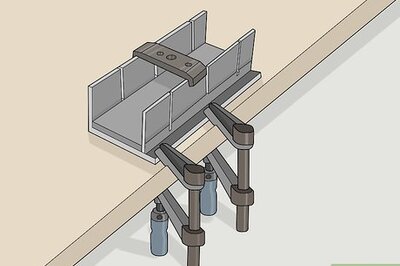

Cut inside corners. For inside corners, which are the most common corner type in a room, you'll have a few different options for how you can cut the molding. The best option, which will adjust the corner if it is not a perfect 45 degrees and let the molding shift naturally as the wood changes with the season and age, will be to cope one side of the molding. To do a cope cut, cut one of the two molding pieces to the exact length of the wall for that side, so that the end butts up against the adjoining wall. Next, cut the second piece at a 45-degree angle, with the back side being the longer side. After that, you'll take your coping saw and cut the end in an opposite 45-degree angle, with the saw carefully following the edge of the front face. Sand the edge once the inside is cut away. This should leave you with a face that looks normal but hides a gap behind it. This allows you to fit it against the other piece of shoe molding like a puzzle piece, create a nice seam. If you can't get or don't want to get a coping saw, or if you're really in a hurry (or you just don't care that much), you can simply miter the ends. The long side of the board, once cut, should be on the back and measure to the length of the wall itself.

Cut outside corners. For an outside corner, simply miter both ends of the two molding pieces. The back side of the molding should fit the measurement of your wall and be the shorter side of the miter. Placing just a bit of glue where the two sides meet can help ensure that the joint stays firm and a gap does not form. Cut diagonal outside corners. Sometimes your baseboards or wall may not meet at a 45-degree angle but instead have a flat, diagonal corner. If this is the case, cut your molding pieces at 22.5 degrees and make sure that the back side of the middle piece matches the length of the diagonal face.

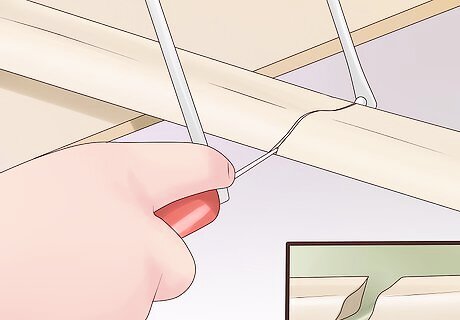

Cut your mid-run joints. If you have a long run that requires two pieces of molding, do not butt together the two ends of molding. Instead, miter cut (45 degrees) both ends in opposite directions so that the two pieces overlap at the joint. This will prevent a visible gap as the wood shrinks and expands over time.

Installing the Molding and Creating Your Returns

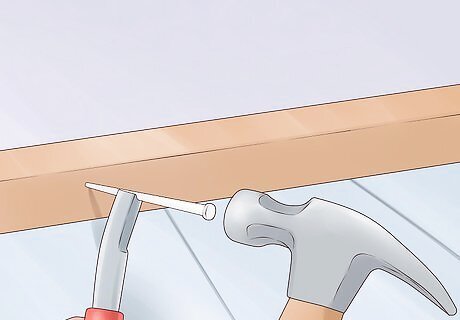

Nail the molding into place. With all of your molding ready to go, you can start nailing it into place using the pneumatic nail gun. Nail at the center line of the molding, to help prevent cracks. How far apart the nails are depends on how secure you want it to be but roughly every 1–2 feet (0.3–0.6 m) should do it. Make sure that your nails are going straight into the baseboards and not angled down into what is probably a gap or floorboards. To do this, you'll probably have to have the nail gun on the floor.

Counter-set the nails. If you have a nail setter, setting the nails will allow you to get a more professional appearance. Place the nail setter against the nails and tap it with a block or your hand to counter-sink the nails.

Choose and create a return.You will run into places where the shoe molding will end, such as at doors and some corners. You need to decide how you want the end to look since it will often stick out from the rest of the molding. There are a few options: Consider a mitered return. This is the most common method of creating a return and probably the easiest. Miter cut the end of your last piece of molding and then carefully miter cut a tiny single piece. Place them together so that the molding turns back into the wall, creating a much cleaner look. Consider a bull-nose return. A bull-nose return is another option, although it requires more tools. Essentially, cut the molding to the length you want it to reach and then use the coping saw and sandpaper to round the end down until it looks nice on its own. Consider a wrap around with no return. Under some circumstances, it may be possible to skip returns by having the molding wrap around a doorway and continue on into the next room. This is not ideal for all homes, however, so only do this is it makes sense and looks nice.

Adding Finishing Touches

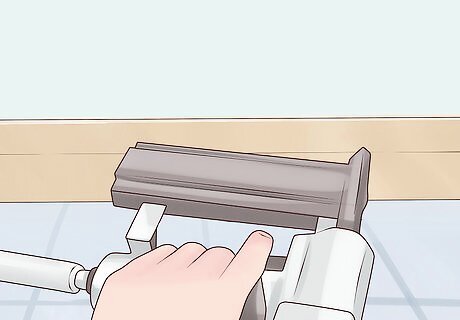

Caulk gaps to create a smoother look. Once you've got all the molding installed, use caulk to fill any gaps at the corners and other gaps. Be aware, however, that if there are gaps between the molding and your baseboards, you may have simply placed your nails too far apart and adding an intermediate nail may help.

Use a nail crayon to cover the nails. Use a nail crayon, if you want to, to fill in the holes created when you countersunk the nails.

Paint or stain your molding. With everything else done, all that remains is to stain or paint the molding however you want it to look. This is easiest when the baseboards are also unfinished, but if your baseboards are already stained you might want to stain the molding before installing it. Once your paint or stain is dry, you're all done! Enjoy your new, professional-looking room!

Comments

0 comment