views

Baking Polymer Clay

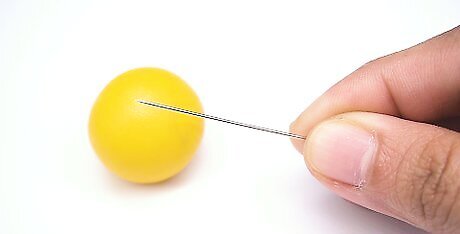

Use a needle to recreate a vent hole if your model has an air pocket. For models that have a closed-off pocket of air, include a vent hole to prevent cracking due to temperature changes in the oven. Pierce the clay with a needle all the way through until you reach the inner air pocket. Keep in mind, some clays aren’t meant to be hardened, such as oil-based modeling clay, so check the packaging of the clay that you’re using to make sure it’s possible! If you don’t have an air pocket in your model, don’t worry about creating vent holes! Be sure to pierce at least 1 hole for each air pocket to ensure proper venting. For example, many clay models of animals have an air pocket inside to make them lighter. Additionally, jewelry like earrings and pendants can have air pockets, especially if they’re very intricate pieces.

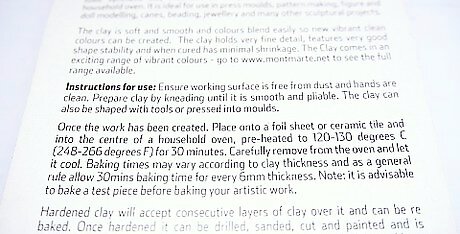

Read the directions on the package to locate the baking temperature. Most brands have the amount of temperature labeled on the package, which can range from 212.5 to 300 °F (100.3 to 148.9 °C). Check the packaging to see if the baking temperature changes based on the thickness of the clay, and set the temperature on the oven. If you’re using multiple different brands of clay in one model, go with the directions for the brand that you used the most. If you’re not sure, set the temperature to 265 °F (129 °C).

Place the clay on a ceramic baking dish. While the oven heats up, transfer your clay model onto a piece of oven-safe ceramic. You can use a baking dish, like a ceramic pie dish, or even a ceramic tile. Ceramic holds heat well and prevents the temperature from changing too quickly when the oven door is opened. Avoid using metal or glass, which tend to fluctuate in temperature. Bake the clay over a surface that you're not going to reuse for food, as polymer clay has a lot of colorants.

Bake the clay immediately after painting or glazing. One of the great things about painting polymer clay is that you don’t need to let the paint dry before baking the clay. As soon as you’re finished covering the model in 1-2 coats of paint, fire up the oven to prepare for baking. Adding a glaze or paint might add to the baking time of your model. In general, for each coat or paint or glaze, add 3-5 minutes onto the baking time.

Bake the clay for the amount of time specified on the package. Most brands of clay have a bake time somewhere between 10-30 minutes, depending on the thickness and color of the clay. As a general rule, bake for the amount of time specified on the package for each ⁄4 in (0.64 cm) of thickness. For example, if the package says to bake for 15 minutes, and your clay is ⁄2 in (1.3 cm) thick, then you would bake the clay for 30 minutes. If you’ve lost the packaging, it’s generally safer to bake at a lower temperature for a longer period of time, like 30-40 minutes.

Fill a large bowl with ice and water while the clay is baking. Get a large cooking pot or bucket that will fit your clay model. Then, fill it with ice water, with about 2 inches (5.1 cm) of space at for the water displacement. You want the clay to be completely submerged in the water, so try to use as large of a pot as possible.

Remove the clay from the oven and dunk it into the water immediately. Once the clay has reached its baking time, use a spatula to separate it from the ceramic. Carefully transfer the model to the pot, and submerge it in the ice bath for at least 30 seconds to prevent the clay from over-baking. Then, carefully remove the model with your hands or a pair of tongs. When you remove the clay from the oven, it might be somewhat soft on the outside, and some tools, like tongs, can leave marks and indentations on the hot clay. Only use the tongs to remove the clay from the ice bath, not put it in. If you’re not sure how to transfer the model, try submerging it while it’s still on the ceramic.

Drying Self-Hardening Clay

Let the clay sit for 24-48 hours to dry. Keep the clay in a dry, well-ventilated area, and leave it undisturbed. Every 4-6 hours, check on the clay to look for cracks or chips, and make sure the clay is hardening. The drying time will vary based on the thickness of the clay and the moisture in the air, but most types of air dry clays will be completely dry within 72 hours. If your clay isn’t hardening after 12 hours or so, try increasing the temperature by blowing the clay with a hair dryer, or placing it in the oven on the lowest temperature for 1-2 hours. Check on the clay often.

Repair any cracks that appear during the drying process. As the clay begins to dry, you might notice some cracks or dents forming in the clay that weren’t there before. To smooth them over, dip your fingers into a glass of clean water, and rub the water over the imperfection a few times to smooth it out. If you notice larger cracks forming throughout the drying process, you may need to rework the project by reviving the clay. This involves adding a small amount of water to the clay, and placing it in a plastic bag to sit for about 10 minutes. Then, knead the clay and continue adding small amounts of water until it is usable.

Turn the clay after 12-24 hours have passed. If your clay model is multidimensional, like a pot or a piece of jewelry, flip the piece over to let the bottom dry. You should do this about halfway through the drying time, which will vary depending on the type of clay you’re using. When handling the clay, be very careful. Try to avoid touching it for longer than you absolutely need to.

Wait to paint the clay until after it has dried. Adding color or a design to your clay is easy. Simply wait until the clay has dried, and use a paintbrush to apply acrylic or tempera paint. Then, let the paint dry for 24 hours, and protect the paint by using a spray-on or brush-on paint sealant all over the clay. If you’re making an intricate design on a clay pot, for example, make sure you use a thin, fine paintbrush, and seal the entire pot after the paint has dried.

Comments

0 comment