views

The cultivation of chlorella has the longest tradition in Asiatic countries, especially Japan, where it has been used for human nutrition, pharmaceutics and cosmetics in an annual amount of several thousands of tones. The use has lately involved the so-called aquacultures - in which the alga is a valuable component of the food chain in directed intensive-breeding colonies for delicate fish and shrimp species.

Chlorella is easy to find and to select the starter strain because it grows in almost any pond or lake worldwide. Alternatively, just buy the starter strain from a local university or biology lab.

Growing Chlorella

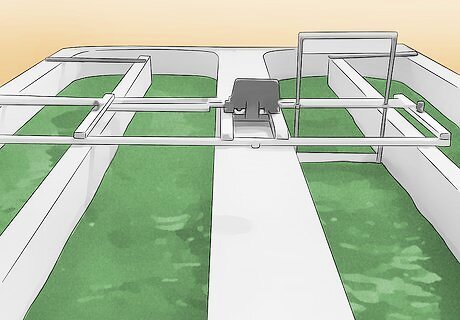

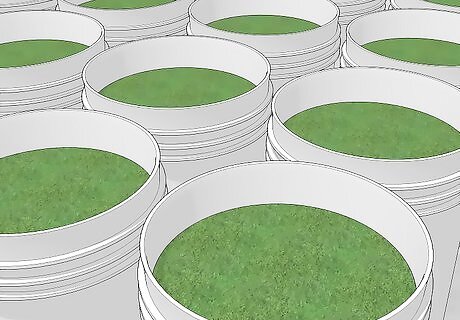

Where to grow and how: Chlorella is usually grown in concrete circular ponds up to 45 m in diameter, with agitation by a rotating arm (resembling a clock dial with the second hand running around). or, in horizontal oblong basins (known as "raceway ponds") in which a 20–30 centimeter (7.9–11.8 in) thick layer of inorganic nutrient solution with algae, exposed to sunlight and bubbled by carbon dioxide, is continuously moved by means of paddlewheels.

The Tøeboò culture technology: This technology developed and optimized since 1960, is very different. It is based on a system of inclined areas on which the algal suspension continuously flows during the day in a very thin layer at an optimum velocity, being thus intensively mixed. The flow velocity and the roughness of the cultivation surface determine the turbulence. Intensive turbulence optimizes the changes of light and dark periods of individual algal cells, resulting in a high efficiency of light utilization. During the night, the algal suspension is stored in aerated collecting tanks. The one-sided inclined area of the first bioreactors was covered with closely spaced transverse baffles, which slowed down the suspension flow velocity and maintained the desired 5-cm layer of algae on the surface. The currently used bioreactors, on the other hand, are composed of two baffle-free flow areas inclined in opposite directions and arranged in a meandering way. Because the flowing algal layer is only 6 mm thick, the suspension volume per unit area is 50 times smaller and the algal concentration 50 times higher than in the basins. This configuration considerably reduces the energy demands for the circulation of the suspension during its cultivation and for the separation of the algae from the nutrient solution during its harvest.

Optimization of the cultivation technology and the use of high-performance algal strains: This makes it possible to achieve high yields of the Chlorella biomass under suitable climatic conditions. While in Tøeboò (located at 50o N latitude), the growing season lasts 150 days and the yield is 16 - 20 tones algal dry weight per 1 hectare unit area, in southern Europe or North Africa, where the annual growing season lasts up to 300 days, the yields are up to 3 times higher.

Processing Chlorella

After the algae have grown sufficiently. To attain a density of approximately 30 g dry weight per 1 l nutrient medium, the algae are harvested. The first step is the concentration of the suspension on disc centrifuges. The concentrated algae are repeatedly washed with water in order to remove remnants of the nutrient solution and other impurities. To achieve the maximum benefit of the valuable cell contents that are enclosed in a tough cellulose 'coat' (a fitting analogy might be the leather 'coat' of a football), we developed a procedure such that the algae pass through a device in which they are mechanically disrupted.

Although the concentrated suspension contains up to ten billion cells per milliliter, the proportion of disrupted cells after two to three-minute disintegration reaches more than 90 %. The grinding of cells increases two to three-fold their digestibility - achieving values comparable with the digestibility of pure proteins.

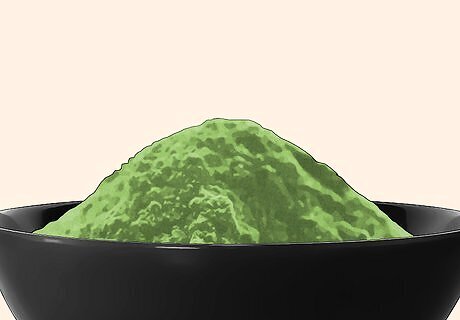

the last step in the processing is the drying. This takes place in spray driers - in which the algal biomass is distributed into micro-droplets whose surface temperature does not surpass 60 °C (140 °F) during the entire 50 seconds for which the drying period lasts. The whole processing procedure is a very gentle one and the dried algal biomass, with the consistency of dried milk powder, thus retains all the valuable components in their original state.

Comments

0 comment