views

Tightening the Screws

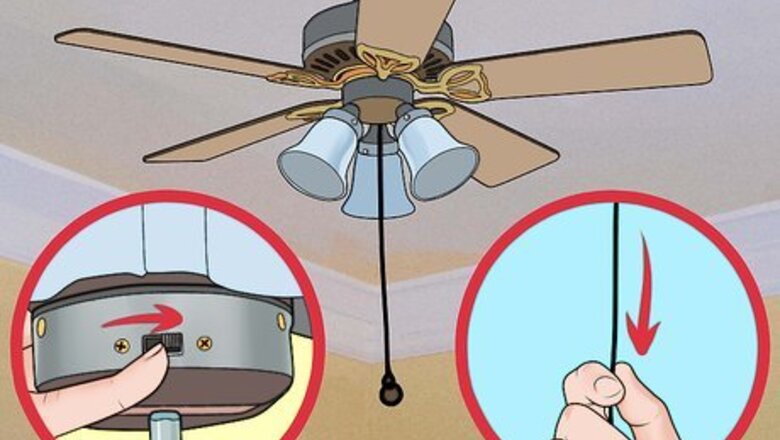

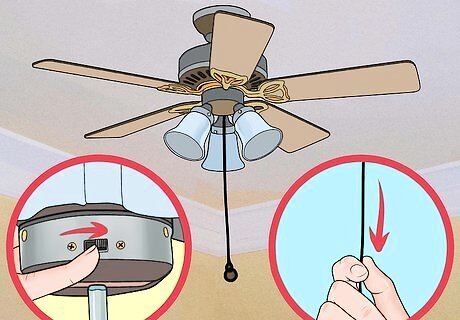

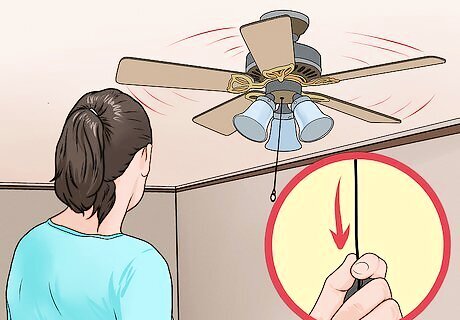

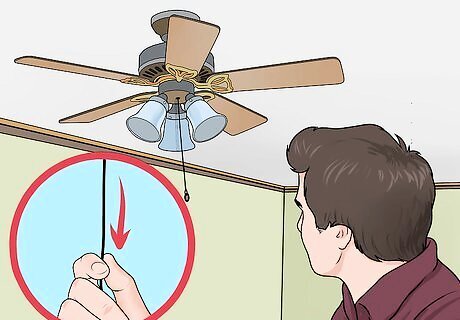

Make sure the fan can't turn on while you work. Switch the fan on, then pull the cord controlling the fan to ensure that, even if someone flicked the switch on accident, the fan won't start turning while you work on it. If you plan on working on the motor, or want to feel extra secure, flip the circuit breaker so that there is no power in the room you are working on. This, however, will make it difficult to test the fan.

Clean the fan blades. Dust, dirt, and debris collecting on the top of the fans can make it off balance, as well as get into the motor or grooves and cause wiggling issues. To clean them: Take a damp, soapy cloth and wipe down each blade to remove dust. A little dusting solution or a drop of dish soap should be enough. Rinse out the soap and wipe up any suds with a clean, damp cloth. Dry the blades by using a clean towel or paper wipes.

Check and tighten all the visible screws on your fan. This includes the screws holding the blades and any connections between the light and fan. Loose screws on any part of the ceiling fan allow parts to move independently, making the whole thing wobble when the blades get up to speed. The screws should all be hand tight, but don't break your wrist trying to get them extra tight. Once they start resisting your turns, you're good to go.

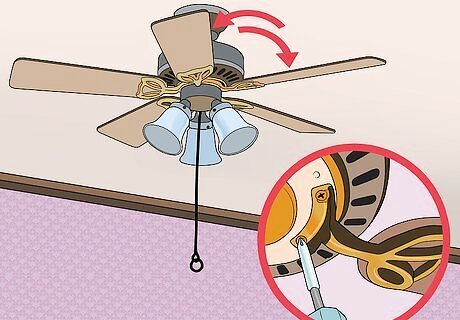

Remove the canopy where the fan attaches to the ceiling and tighten any screws. These screws keep the fan attached, and wobbling will be the least of your worries if they get too loose. Undo the screws and slide the canopy down, then hand-tighten any visible screws where the fan meets the ceiling to ensure that the fan is well attached.

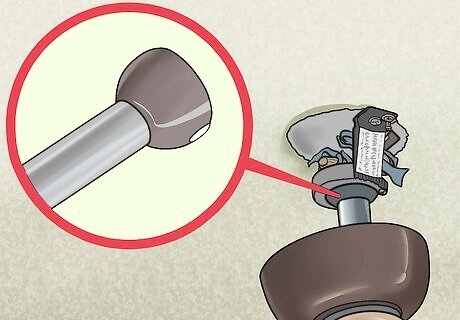

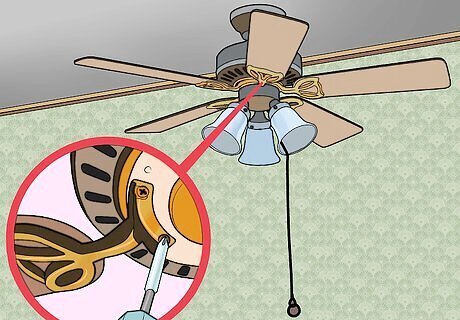

Check the hanger ball before reattaching the canopy. This small ball fits in a similarly shaped bowl like a bone in a socket. Attached to the ball is the center rod of the fan that keeps everything attached to the ceiling. Make sure the hanger ball is completely seated so the ball fits snugly in its joint and doesn't move around. Reattach the canopy when you're done.

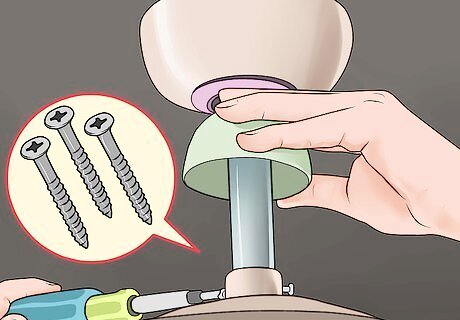

Tighten the downrod support screws. These small screws attach at the top of the motor, where the downrod (coming from the ceiling) meets the body of the fan. There are usually 2-3 screws that keep the fan attached, but they may be covered by a small metal piece to make the fan look more appealing. Simply unscrew or push this covering up the downrod and tighten any screws you see.

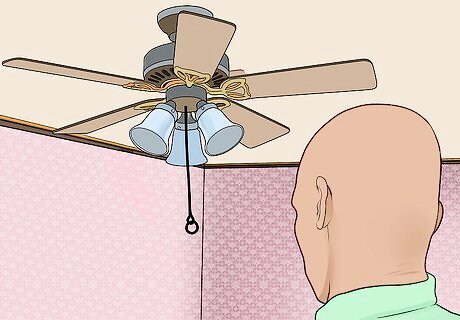

Run the fan on high to check for any wobble. Once you've tightened the screws in the blades, downrod, and mounting, try the fan again and see if you've made progress. If not, the problem likely comes from unbalanced or warped blades. However, keeping the screws tight only takes a few minutes and helps prevent future problems.

Fixing Blade Height Issues

Use a step-ladder to check each blade for warping. Stand at fan height and look down each blade. Do any look warped, cracked, or bent? Check the blade holders, the metal pieces at the base of each blade, and check for any cracks or wear. If you have broken or warped blades or blade holders you should contact your fan's manufacturer for a replacement.

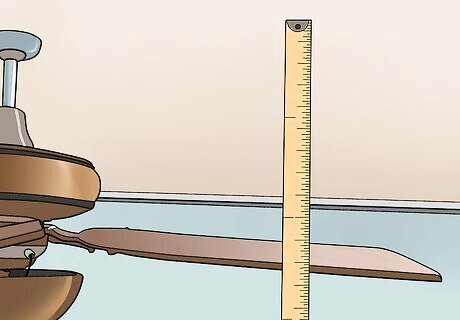

Use a yardstick to measure for equal blade height. Hold the yardstick up to the ceiling and spin the fan so that the outside edge of a blade lines up with the yardstick. Note the height of the blade, and then check the other blades to make sure they are the same. Keep the yardstick in place the entire time, spinning the fan to make sure all the blades meet the yardstick at the same height. Since fans blades are usually tilted, make sure you measure from the same edge on every blade -- the highest corner is usually the easiest to mark. If you don't have a yardstick, a board or piece of paper should work too. Use a permanent marker to note the height of each blade, keeping your measurement instrument in the same place while spinning the blades.

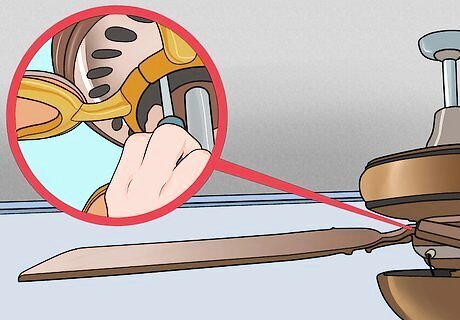

Tighten the screws connecting the blade hanger to the motor for any low blades. This screw may be covered up or hard to reach, but it is found where the blade hanger (metal piece attaching the wooden blade to the fan) meets the motor. Get in and tighten this screw, which should raise the fan.

Gently bend the blade holders up or down to get them aligned. Do not do this if a blade holder is cracked, as it could cause it to break. However, light pressure can be used to bend the blade to the right height. Hold onto the base of the fan with one hand, keeping it still. Put gentle upward or downward pressure on the blade holder at the point where it meets the blade to align it correctly. Check the height of the blades one more time to make sure everything is well aligned. Remember to use your yardstick and spin the blades instead of moving the measuring stick.

Test the fan. If the wobble is gone, it should stay that way unless someone accidentally clips a blade. A vertical variance of even 1/8" in one blade can cause it to wobble, so make sure you get this right before moving on to fan balancing.

Balancing the Blades

Know that unbalanced blades cause most fan wobbling issues. If there is a weight difference of even .5 grams you will be in for some wobbling when things start spinning at high speeds. This could be the result of improper installation, fan wear, or simply poorly designed blades.

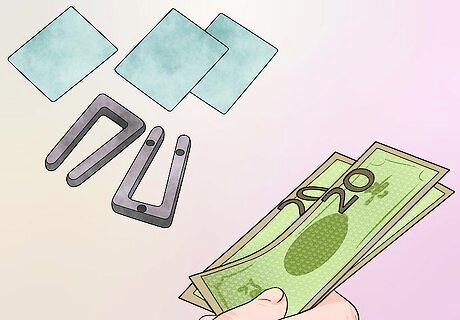

Purchase a blade balancing kit, or make your own. Blade balancing kits are simply small weights that you use to get your fan running smoothly. They consist of weighted clips and/or several adhesive weights meant to attach to your fan blade, allowing you to adjust the weight slightly and get everything balanced. Though balancing kits are cheap, you can use tape and a few nickels and dimes to make your own balancing kit at home, though the need to tape and untape the coins makes the process take a little longer.

Hook the balancing clip on the center of a blade, using the edge angled higher. These small clips add weight to the blade, allowing you to test which one is ruining the balance. Turn on the fan and note if the wobble is reduced. Move the clip to another blade, testing each one until your find out which one is causing the problem. Look for the blade that, when the balance clip is attached, lowers the wobble the most. To test without a kit, tape a nickel in the center of a blade, then test it. Remove the nickel and try another one until you find the culprit.

Slide the balancing clip up and down the blade, testing each time. Once you've found the unbalanced blade, move the clip up 6 inches, then test it again. Move it down towards the base and test that too, looking for the spot where the fan spins the smoothest. There are apps available which will help you find the best spot for the clips to remove the wobble.

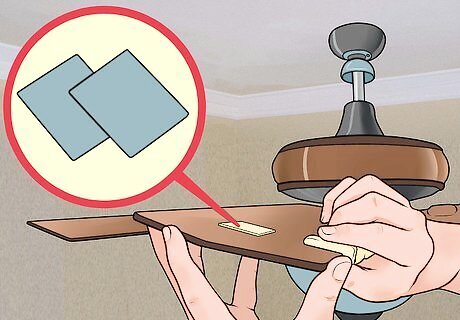

Attach a balancing weight at the location of the balancing clip, in the center of the blade. Once you know where you need to balance the fan, remove the adhesive backing to the weight and stick it on the blade so that it is lined up with the balancing clip. Remove the clip and test the fan again. If the fan starts wobbling again after you remove the clip, attach a second, smaller weight next to the first one to make up for the weight of the balancing clip.

Swap the blade positions if more than one blade is out of balance or if the fan is wobbling right after installation. If you can't find one blade that is out of balance they may have been installed incorrectly. If your fan is brand new, you may have simply added the fans in the wrong order, and switching out the blades should fix your issue. Use post-it notes to label the blades (1,2,3,4,5), then switch them by unscrewing them from the blade mounts and reattaching them to the correct mount. For 4-blade fans, swap a set of neighboring blades and turn the fan on again to test. For 5-blade fans, swap blades two away from each other (such as the first blade and the third) and test. It may take 2-3 tries to get the right order.

Comments

0 comment