views

Planning

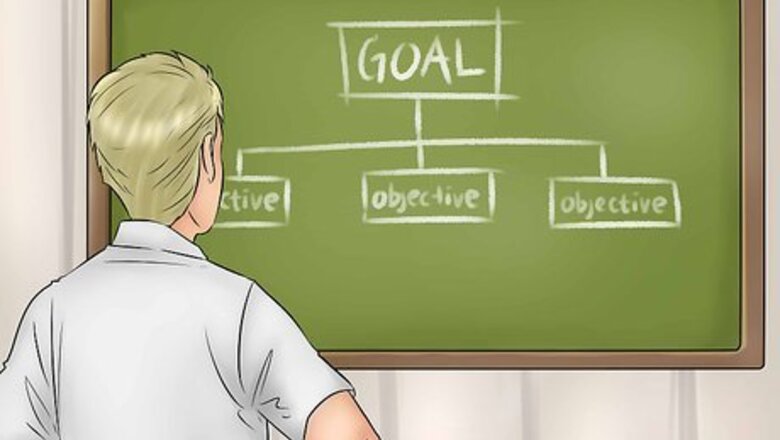

Set an objective: What is the goal of this forge? What will the end product be? Questions like this are based on what you want to make or work with, as well as the amount of use the forge.

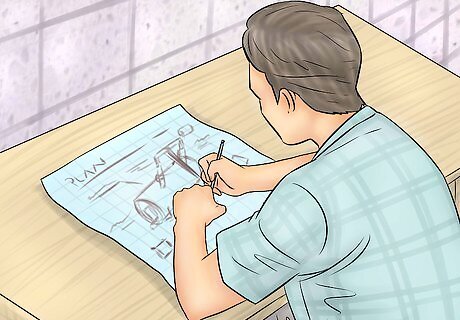

Make a tentative plan. Take the goals and decide on these factors: Number of burners, size of forge, amount of usage, budget, short-cuts (do you already have a major component of a forge?), etcetera. Where the forge will be built and operated is important (this forge must be operated outdoors).

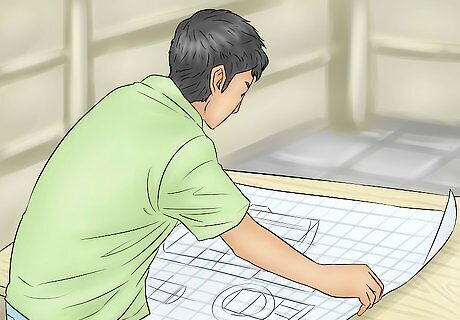

Finalize the plan. Create a parts list as based on forge design. Affirm "blueprints" as to what the forge will be, part by part, and based on size.

Gather parts. This can be done progressively as you make your way building components. You can build a gas forge with a $0 budget, but you'll need to scavenge parts.

Building

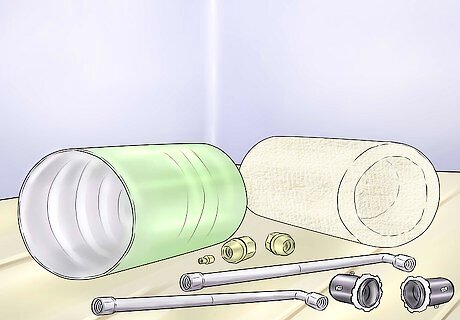

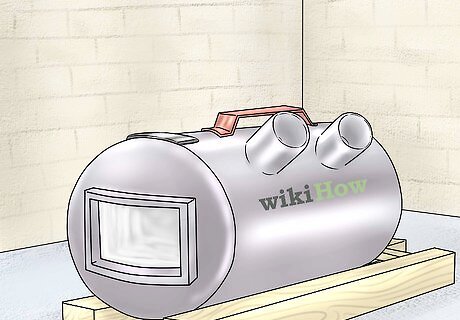

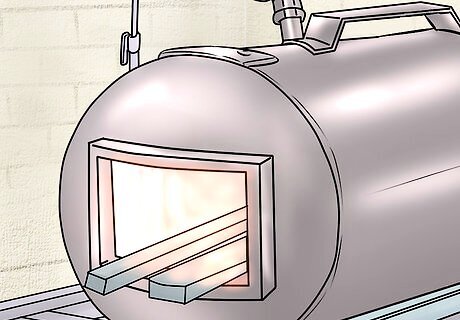

Build the forge body. There are two major ends of the gas forge, which are the body and the burners. The body can be any metal container such as an air tank or 5 gallon (18.9 L) paint can. This needs to be lined with an insulating layer. Firebrick is cheap but very inefficient, while high-temperature ceramic fiber blanketing is expensive and holds heat very well.

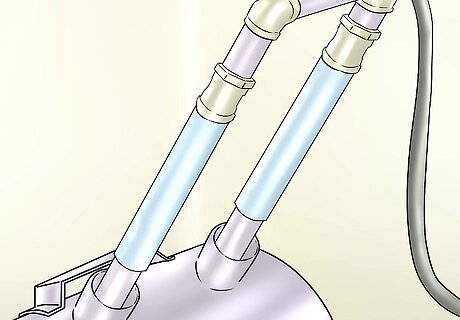

Set up the burners: The most practical way to build the propane burners is to buy a book. A book on homemade propane burners will offer insight on propane safety, engineering considerations, and efficiency. There are ways to make burners from mig welding tips and steel pipe, as shown above. This picture depicts two propane burners with air chokes, mig-welding tip nozzles, and a shut-off to use just one burner. If budget is a major concern and your forge design is smaller than 200 cubic inches (roughly) a propane bottle torch can be used.

Set-up work area. A forge stand is good if it needs to be used and moved a lot. The forge needs to be outside during operation. Properly ventilating not only the heat but the output gasses is a project on its own and doing so improperly will lead to property damage and/or death. The picture depicts a dolly style forge cart which holds the propane underneath with tool storage. The propane bottle is removed and place away from the forge when in use.

Testing and Operating

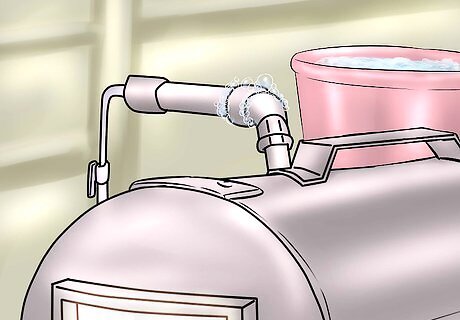

Test the forge. Use soapy water to test whether the gas line leaks or not with pressure. Use a medium-sized metal file to see how hot the forge can get and how fast it heats up. When in use, take note of how long gas lasts to budget how much work can be done on a can of propane.

Use the forge. Always wear safety glasses during all work. Large and hot forge work should be done with IR protective glasses. If you are a home hobbies, try these experiments: Use a metal file, examine the amount of sparks produced when on a bench grinder. Anneal the piece and examine again. Quench the piece in water at an orange heat and try again. Try making a round bar square if you have an anvil. Make a twist in a square bar with a vice and pliers. Heat a scrap metal file as hot as it can go. If it turns white and 'burns,' the forge is efficient enough to faggot-weld with. If it does not reach this temperature, it is fine. Try faggot-welding two rods together using borax.

Comments

0 comment