views

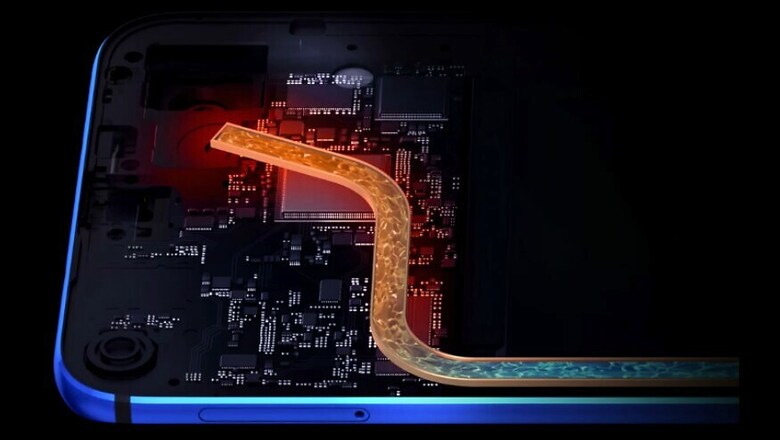

Inspired by the sweating mechanism in mammals, scientists have developed a new coating that can prevent smartphones and laptops from heating up by releasing water vapour. The new thermal management method, described in the journal Joule, could keep electronics cooler compared to existing strategies by dissipating excess heat. "The development of microelectronics puts great demands on efficient thermal management techniques, because all the components are tightly packed, and chips can get really hot," said Ruzhu Wang, from Shanghai Jiao Tong University in China.

"For example, without an effective cooling system, our phones could have a system breakdown, and burn our hands if we run them for a long time, or load a big application," Wang said in a statement. Larger devices such as computers use fans to regulate temperature, the researchers said. However, fans are bulky, noisy, and energy consuming, and thus unsuitable for smaller devices like mobile phones, they said.

Manufacturers have been using phase change materials (PCMs), such as waxes and fatty acids, for cooling phones, by absorbing heat produced by devices when the materials melt. However, the total amount of energy exchanged during the solid-liquid transition is relatively low. In contrast, the liquid-vapour transition of water can exchange 10 times the energy compared to that of PCM solid-liquid transition. Wang and his team studied a group of porous materials that could absorb moisture from the air, and release water vapour when heated.

Among them, metal organic frameworks (MOFs) were the most promising because they could store a large amount of water, and thus take away more heat when heated, the researchers said. Previously, researchers have tried to use MOFs to extract water from the desert air. However, MOFs are still really expensive, so large-scale application isn't really practical. "Our study shows electronics cooling is a good real-life application of MOFs. We used less than 0.3 grams of material in our experiment, and the cooling effect it produced was significant," Wang said.

The researchers selected a type of MOFs called MIL-101(Cr) for the experiment because of its good water-absorbing capacity, and high sensitivity to temperature changes. They coated three 16-square-centimetre aluminum sheets with MIL-101(Cr) of different thicknesses -- 198, 313, and 516 micrometers, respectively -- and heated them on a hot plate. The team found that MIL-101Cr coating was able to delay the temperature rise of the sheets, and the effect increased with coating thickness.

While an uncoated sheet reached 60 degrees Celsius after 5.2 minutes, the thinnest coating doubled the time, and didn't reach the same temperature until 11.7 minutes, the researchers said. The sheet with the thickest coating reached 60 degrees Celsius after 19.35 minutes of heating, they said.

Comments

0 comment