views

In a world grappling with plastic pollution, hemp-based bioplastics emerge as a sustainable solution. Derived from the versatile hemp plant, these bioplastics offer biodegradability, renewability, and reduced carbon footprint, addressing pressing environmental concerns. With a growing emphasis on sustainability across industries, hemp bioplastics represent a pivotal step towards a greener future, fostering innovation and circularity in packaging practices.

The ubiquitous presence of plastic in our lives is undeniable. From grocery bags to water bottles, plastic offers convenience and durability. However, its environmental cost – overflowing landfills with an estimated 8.3 billion metric tons of plastic waste as of 2021, microplastics in our oceans, and dependence on fossil fuels – is becoming increasingly apparent.

In the dynamic contemporary landscape, the imperative of sustainability has gained paramount prominence for businesses. The worldwide waste management sector, valued at USD 423.4 billion in 2021, is earmarked to reach USD 542.7 billion by 2026, growing at a compound staggering annual growth rate (CAGR) of 5.1% from 2022 to 2031.

Abhishek Agashe, co-founder & CEO, Elima, says, “The governments and various organizations globally are increasingly compelled to enhance their waste management infrastructures by emphasizing reuse, recycling, and waste-to-energy conversion due to escalating social and environmental concerns. By embracing the motto ‘Every Person’s Responsibility matters,’ individuals can collectively contribute towards building a more sustainable future, where resources are conserved, waste is minimized, and environmental impacts are reduced; thus moving an inch closer towards powering the circular economy and bolster sustainability efforts. This will also boost individuals and companies to innovate and develop solutions for creating a more sustainable living ecosystem whilst powering circularity, which is a need of the hour to achieve the set goals for the ‘Mission 2047 Viksit Bharat.’ ”

Sandeep Kumar Tyagi, Co-Founder, COO, Ukhi India, says, “Hemp-based bioplastics emerge as a beacon of hope, offering a sustainable alternative for the packaging industry. Derived from the fast-growing hemp plant, these bioplastics are biodegradable, renewable, and require less energy to produce compared to traditional, petroleum-based plastics.”

The Environmental Case for Hemp-Based Bioplastics:

Tyagi shares the environmental benefits of hemp-based bioplastics are numerous:

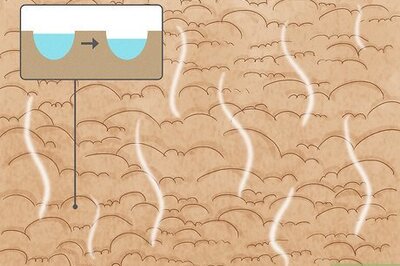

- BiodegradableUnlike traditional plastics that can persist in landfills for centuries, hemp bioplastics decompose naturally within a few months. This significantly reduces plastic pollution and its detrimental impact on ecosystems.

- Renewable ResourceHemp is a fast-growing crop that requires minimal water and thrives in various climates. It can be harvested multiple times a year, with estimates suggesting yields of up to 25 tons per hectare. This makes it a readily available and sustainable resource.

- Reduced Carbon FootprintHemp cultivation absorbs carbon dioxide from the atmosphere, at a rate of up to 15 tons per hectare. Additionally, the production process of hemp bioplastics requires less energy compared to traditional plastics, resulting in lower greenhouse gas emissions.

- Reduced Reliance on Fossil FuelsHemp bioplastics offer a path towards weaning off our dependence on fossil fuels as a source for plastic production. This fosters a more sustainable and secure future.

Hemp Bioplastics: Advantages Beyond Sustainability

While environmental benefits are a major driver, hemp bioplastics offer additional advantages:

● Versatility: Hemp bioplastics can be molded into various shapes and forms, making them suitable for a wide range of packaging applications, including food containers, bottles, and films.

● Durability: Hemp-based bioplastics are surprisingly strong and can be customized to meet specific requirements for strength and flexibility.

● Non-Toxic: These bioplastics are non-toxic and pose no health risks, making them ideal for food packaging.

Comments

0 comment