views

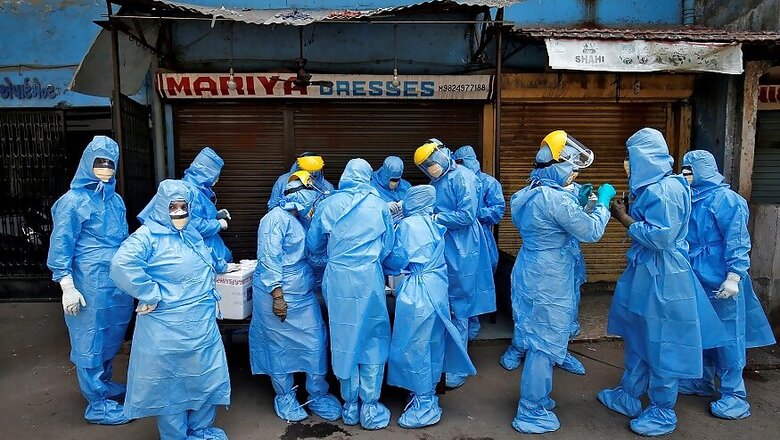

New Delhi: Leading institutions of the country have developed a mission-critical personal protection kit for health workers to fight the deadly coronavirus infection, the World University of Design said in a statement on Monday.

The prototypes of PPE Kits are currently undergoing the second round of testing in a Chennai hospital and are expected to go into production within this week, World University of Design vice chancellor Dr Sanjay Gupta said.

IIT Delhi, AIIMS, World University of Design and Chennai-based extile Mills have jointly developed the kit, he mentioned.

"The design and production of these kits is open source, therefore any small or medium scale factory interested can take the design from us and start manufacturing them. The key feature of this design is the ease of doffing, where the garment can be taken off by the person without touching the infected outer surface. The prototypes for these kits have been created following the required protocol," Gupta said.

There has been a huge shortage of PPE kits and hundreds of health workers have fallen prey to coronavirus in absence of his mission critical tool.

According to the health ministry update on Monday, the death toll due to the coronavirus has reached 559 and the number of cases has risen to 17,656 across the country.

However, a PTI tally of figures reported by various states and union territories, as of 6.30 PM, showed 17,744 confirmed cases, 2,859 recoveries and 584 deaths. Maharashtra alone has reported 4,600 cases, while Delhi has also crossed 2,000. Gujarat has over 1,800 cases, while Tamil Nadu and Rajasthan are above 1,500 each, closely followed by Madhya Pradesh at over 1,400.

Some of the Indian firms have started manufacturing PPE kits in small quantities.

Gupta said that a team of researchers from WUD has designed the PPE sets keeping in mind the ease of donning and doffing the PPE without help.

"These sets are designed to make them fit Indian body shapes and sizes. They help avoid loose, hanging parts which may come in contact with infected surfaces and get contaminated. There are no unnecessary openings which may aid the contagion to pass through the PPE, thereby infecting the person in question. Even micro-openings created while stitching the garment, which may provide a pathway for the virus to enter, are sealed off along with the seams," the statement said.

Loyal Textile Mills will start production once the suit sealing machine reaches the factory.

"The design involving a minimum number of seams not only minimizes the risk of seam leakage but is also fast and cheap to produce. Special barrier fabrics which are breathable and provide the highest liquid barrier protection level are used to make the PPE. A combination of all this makes it the perfect PPE kit designed to meet the challenge posed by the covid-19," the statement said.

A PPE kit includes goggles, face-shield, mask, gloves, coverall/gowns (with or without aprons), head cover and shoe cover.

The World University of Design and IIT Delhi have been working closely on the research, development and promotion of functional clothing for various medical applications.

Comments

0 comment