views

Patching Straight Holes with Wood Filler

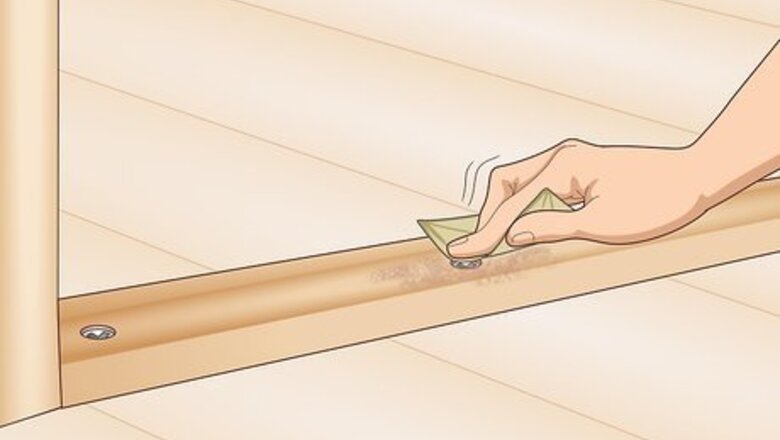

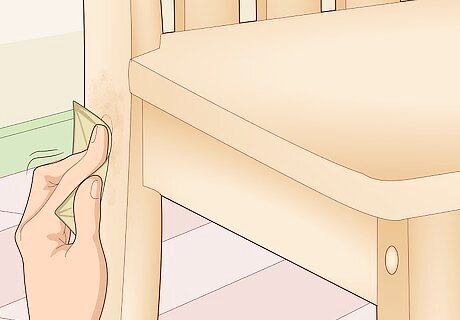

Sand down any rough edges around the screw hole if necessary. Sometimes, screws can cause minor damage to wood surfaces as they’re driven in. If this is the case with the surface you’re patching, grab a sheet of medium- or high-grit sandpaper and go over the area using light, circular strokes. The sandpaper will help remove splinters, loose chunks, and other irregularities. A sandpaper with a grit between 100 and 120 will offer the right balance of abrasion and smoothness.

Clean the surface with a damp cloth or paper towel. Wet a clean, lint-free cloth or sturdy paper towel and squeeze out the excess water. Run the cloth or paper towel over the screw hole and surrounding wood. Allow the area to dry completely when you’re finished. Before you actually begin filling the hole, you want to make sure that it’s completely free of dust, dirt, or debris that might otherwise find its way into your filler and prevent you from getting a consistent finish. Steer clear of cheap paper towels. These have a tendency to shed tiny bits of paper that can leave the wood in worse shape than it was in to begin with.

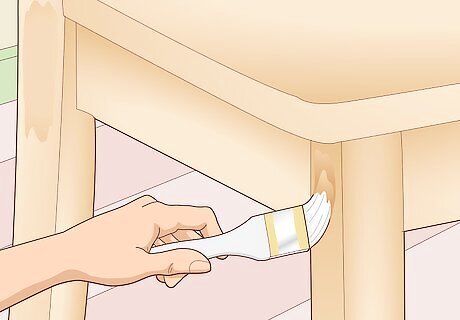

Scoop enough wood filler into the hole to overfill it slightly. Use the tip of a putty knife to transfer a liberal amount of filler into the hole, then smooth it with the flat part of the blade until it’s level. Ideally, the smoothed wood filler should sit just above the surface of the wood. The key to getting a seamless finish is to use more wood filler than you think you need, as most fillers tend to shrink as they dry. If you go a little overboard with the wood filler, simply turn your putty knife onto its side and scrape off the extra compound with the edge of the blade. Be sure to select a stainable type of wood filler if you're planning on staining your surface.Alternative: Whip up your own easy homemade wood filler by mixing together equal parts high-strength wood glue and sawdust from scrap wood with a color similar to that of the surface you’re working on.

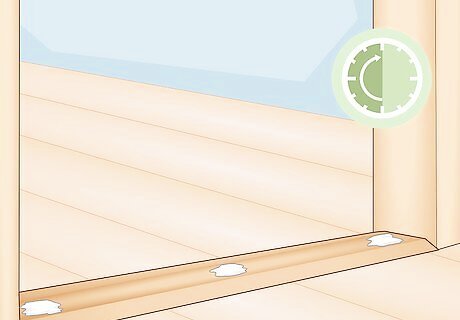

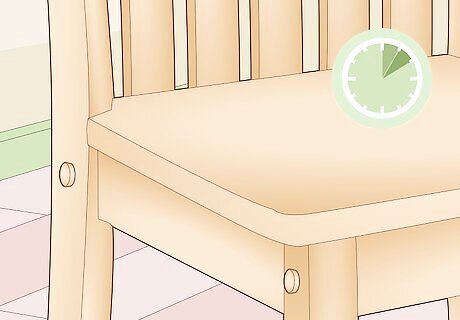

Let the wood filler dry for at least 30-60 minutes. Avoid touching or make any further adjustments to the patch while the filler is drying. Doing so could smear or leave behind noticeable depressions in the still-wet compound, ruining all your hard work. Most wood fillers are formulated to harden within about an hour, but drying times can vary between products. Be sure to check the label of the wood filler you’re using for more specific drying instructions. To cut down on your overall project time, apply your wood filler in a dry, climate-controlled indoor space. Heat and moisture could extend the product’s drying time. For the best, longest-lasting results, allow the wood filler to cure overnight.

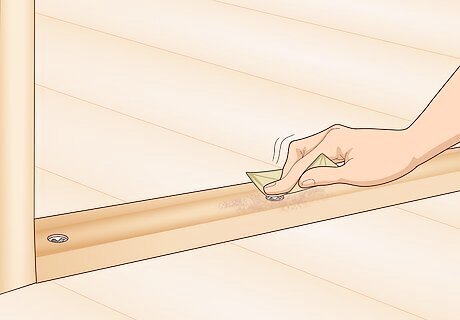

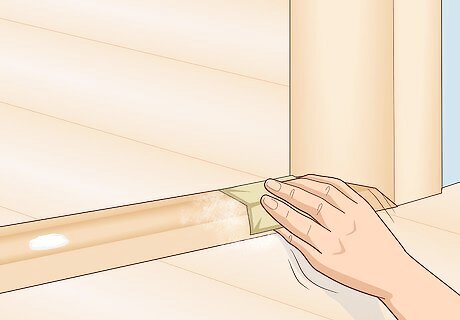

Sand the filled hole and surrounding wood smooth using high-grit sandpaper. Glide the sandpaper over the hidden screw hole with fluid, circular strokes with moderate pressure. Sand thoroughly, but don’t overdo it. Your goal here is just to blend the filler into the wood to make the patched spot less obvious. A 150- to 220-grit sheet of sandpaper will do the best job of evening out the filled hole without leaving behind scratches or other visible imperfections. A high-powered orbital sander or sanding block will also work well for this task.

Paint or stain the patched area if desired. Once you’ve successfully filled and sanded the screw hole, you can go on to add one or more coats of paint or stain in your preferred shade. Don’t forget to brush on an appropriate primer or wood conditioner to prepare the filler and the wood around it to accept the new finish. You also have the option of leaving the surface as-is if you want to preserve the natural look of unfinished wood. Just keep in mind that the patch won’t be completely invisible.

Hiding Pocket Holes with Wooden Plugs

Pick up some wood plugs in a color that matches your surface. Wood plugs are small, round wooden rods that have been cut with a sharp slant on one end to fit easily into pocket holes, or the shallow, angled openings formed by countersunk screws. They’re sold in a variety of shades meant to simulate the appearance of different wood finishes, including pine, oak, and maple. You can purchase a package of wood plugs for just a few dollars at any hardware store or home improvement center, as well as online. Wood plugs are sold in standardized sizes that match the dimensions of many of the most common types of screws. This means you shouldn’t have a problem finding a plug that’s just the right fit. There are also wood plugs with a cylindrical shape, which can come in handy for filling straight screw holes drilled at 90 degrees.

Make your own DIY plugs using a plug cutter or wooden dowels. Scrounge around for a piece of scrap wood with a finish that resembles that of your surface. Then, fit a drill press with a pocket hole plug cutter attachment and use it to score and punch out a plug roughly ⁄2–2 inches (1.3–5.1 cm) in length. Alternatively, you can take an ordinary wooden dowel and trim it so that it’s just long enough to fit into the screw hole, with ⁄4–⁄2 in (0.64–1.27 cm) of material left sticking out. Fashioning your own wood plugs can be a good solution if you know your way around a set of woodworking tools and want to save on the cost of materials.

Apply a thin layer of wood glue to the bottom surface of the plug. Dab the glue directly onto the plug, or squeeze some out onto a separate surface and dip the plug in by hand. Whichever method you go with, try to coat the entire plug evenly to improve the glue’s ability to bond and make sure the plug will hold. If you’re working with an angle-cut plug, the bottom surface will be the angled face. With a cylindrical plug, it doesn’t matter which side you spread the glue on. Most wood glues begin to dry in a matter of seconds, so be prepared to work quickly once you’ve applied the adhesive.

Insert the plug into the screw hole. Slip the plug straight into the hole and press firmly on the upper face until it seats securely. Once it has, there will be ⁄4–⁄2 inch (0.64–1.27 cm) of wood sticking out of the hole. This is completely normal, so don’t worry—you’ll be removing this excess material later on. If you’re having trouble getting the plug to go in, try tapping the backside lightly with a hammer. You’ll need a hammer to coax straight-cut dowel plugs into place, as well.Tip: To make your patch job as inconspicuous as possible, arrange the plug so that the grain on the upper surface is running in the same direction as the grain on your piece.

Allow the glue to dry for 5-10 minutes. It will only take a couple of minutes for the powerful adhesive to cement the plug into the screw hole. Still, it’s a good idea to leave it alone for a few extra minutes just to make sure that it bonds properly. In the meantime, resist the urge to fidget with the plug, as this could cause it to come loose. If you’re not in any particular hurry, consider leaving the glue to cure overnight to reach its full strength.

Use a wood chisel to shear off the upper part of the plug. Hold the tip of the chisel squarely against the edge of the plug where it meets your surface. Then, push the blade into the plug with enough force to cut through the unneeded wood. Run the chisel back and forth over the plug as many times as necessary to shave it down flush with the surrounding surface. Be careful not to bear down too heavily with your chisel. You could end up scarring or gouging the wood if you push too hard. A flush cut saw will also do the trick. Just place a thin spacer down on your surface, lay the blade flat against the spacer, and guide the serrated edge over the excess material using a smooth back-and-forth motion.

Sand the area around the plugged hole to a seamless finish. Run a sheet of 150- to 220-grit sandpaper or a sanding block or orbital sander over the chiseled face of the plug to smooth and blend it. When you’re done, you’ll have to look pretty closely to be able to tell that there was ever a hole there in the first place! Focus on especially rough or uneven areas, like the grooves created by the scraping of your chisel. You may even be able to skip this step if you pared your plug off nice and clean.

Paint or stain the plugged hole and surrounding area. Now that you've filled in the screw hole, you're free to finish the surface however you like. Brush on 1-2 coats of a suitable primer or wood conditioner, then follow up with 2-3 coats of paint or stain in your chosen shade. Allow each coat to dry thoroughly before applying your next one, and let your topcoat dry for at least 24 hours before handling or making any other modifications to the surface. You can use as many as 6-7 coats of stain to achieve a deeper, richer finish. Wood plugs are made from genuine wood, so they can be painted or stained just like any other wood surface. There's no need to paint or stain if you'd rather leave the natural charm of your wood surface on display. When chosen and installed properly, wood plugs are virtually invisible, thanks to their similarities in tone and grain pattern.

Comments

0 comment