views

X

Trustworthy Source

State of New York

Official website for the State of New York

Go to source

If you do choose to refill your own fire extinguisher, follow the guidelines set out in your owner’s manual very carefully in order to ensure your extinguisher functions safely. You’ll need the right kind of chemical extinguishing agent as well as access to pressurizing equipment. You’ll also need to inspect your extinguisher carefully for any signs of damage.

- Empty your extinguisher into a discharge bag, then remove the hose and valve from the tank and wipe them down with a soft cloth.

- Measure out your extinguisher chemical with a scale according to the extinguisher's capacity, then use a funnel to pour the chemical into the tank.

- Reinstall the valve. Then attach the extinguisher to a pressurizing line and pressurize it to the appropriate PSI. Finally, reinstall the hose and ring pin.

Cleaning and Inspecting the Extinguisher

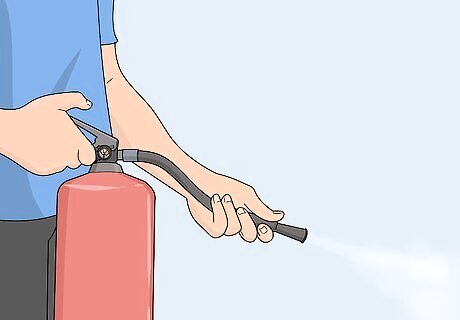

Empty and depressurize your extinguisher completely. Consult the service manual for your fire extinguisher to find the correct procedure for depressurizing it. This typically involves holding the extinguisher either vertically or upside-down and slowly squeezing the discharge handle until the pressure gauge reads “0” and nothing comes out when you squeeze the handle. If you’re using a dry chemical extinguisher, depressurize it by discharging the contents into a dry chemical closed recovery system or a simple discharge bag. You can purchase one of these devices from a fire safety or architectural supply store. You’ll also need a special recovery system for discharging and refilling clean agent fire extinguishers, such as halon or halotron extinguishers. Before performing any further maintenance on the extinguisher, double-check that it’s fully discharged and depressurized by putting the operating valve and shutoff nozzle in the fully open position. There shouldn’t be any discharge from the hose.

Wipe the outside of the extinguisher with a solvent-free cleanser. Use a clean cloth and a mild cleanser, such as warm water and dish soap, to wipe down the extinguisher and remove dirt, dust, and grease. Dry the extinguisher with a clean rag or towel. Don’t use any solvent-based cleaning products, since they could damage the plastic face on the pressure gauge.

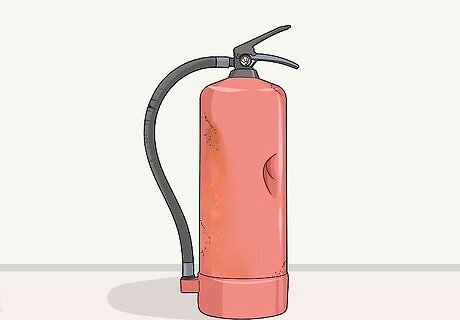

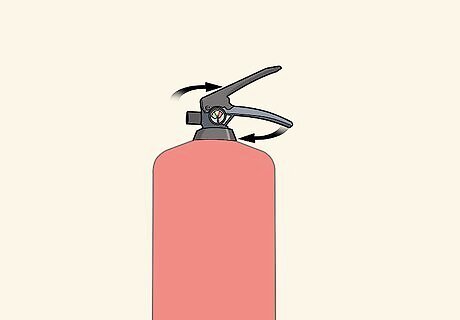

Have the extinguisher repaired or replaced if you find any damage. Check for obvious damage to the cylinder, such as abrasions, dings, rust, or welding damage. Make sure that the nameplate or instruction label is clean, legible, and in good condition. Check for any signs of damage to the other components as well, such as the pressure gauge, ring pin, and discharge valve. If you find obvious damage, take your extinguisher to a fire safety technician so they can evaluate it and decide if it needs to be repaired or replaced. Make sure all the parts of the extinguisher move and operate correctly. For example, check that you can easily remove the ring pin and open and close the nozzle shutoff lever. Check that there are no parts missing, damaged, or replaced with non-factory parts.

Remove the discharge hose from the operating valve. Discharge hoses are typically attached to the valve with a threaded coupling. Use a wrench to loosen it if necessary, then remove it and set it aside. The operating valve is the structure located at the top of the fire extinguisher that controls the flow of the extinguishing agent out of the cylinder. The hose is typically attached to an opening on the valve opposite the levers that you squeeze to release the extinguishing agent. Take this opportunity to inspect the hose, couplings, and hose gasket for any signs of cracks, wear, or damage. If you notice any problems, you’ll need to order replacement parts. Blow into the hose and the nozzle assemblies with pressurized air to make sure they aren’t blocked with any debris. In warm climates, it’s not unusual for insects to move in and block the hose.

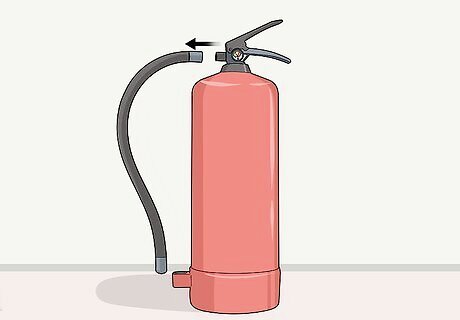

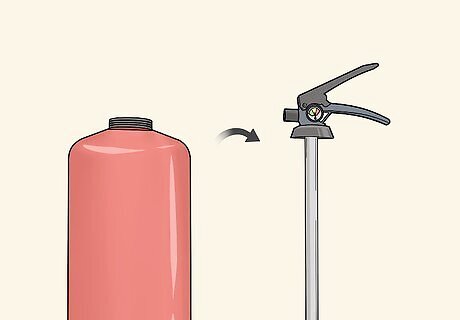

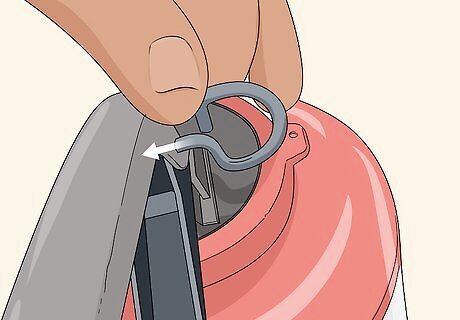

Take off the valve assembly. Finally, you’ll need to remove the valve assembly completely so that you can fill the empty cylinder. Unscrew the operating valve (which includes the hose port, discharge levers, and pressure gauge) from the top of the cylinder. Take care not to scratch any of the inner surfaces of the valve, since this could cause a leak, and never lean over the extinguisher while you are removing the valve assembly. If the canister isn’t completely depressurized, it could come off with great force. Check for any signs of corrosion and damage as you do this. Depending on the model of your extinguisher, you will likely need to: Pull out the ring pin and remove the seal. Use a wrench to loosen the ring holding the valve assembly in place. Carefully remove any inner components, such as the siphon tube.

Refilling the Extinguisher

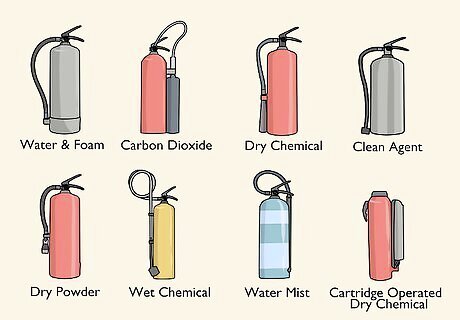

Purchase the correct kind of filler for your extinguisher. Check the label or nameplate on your fire extinguisher to determine what kind of filler you need to use. It’s critical for your safety and the proper functioning of the extinguisher that you use the right kind of filler and don’t mix any extinguishing chemicals. Depending on what kind of filler your extinguisher needs, you may be able to purchase it from a home supply store, online, or from an industrial supply or fire safety store. The types of fire extinguisher fillers include: Water and foam extinguishers, which should only be used on class A fires (fueled by ordinary flammables, such as paper or wood). These extinguishers are filled with water mixed with a special foaming agent. Carbon dioxide extinguishers. These release very cold carbon dioxide to quickly cool a fire. They are only effective for class B and C fires (fires fueled by flammable liquids or electricity). Dry chemical fire extinguishers, which interrupt the chemical reactions that cause a fire. These extinguishers are filled with a variety of powdered chemicals, and many of them can put out class A, B, and C fires. These come in both pressurized and cartridge-operated forms. Wet chemical extinguishers, which cool the burning material and prevent chemical reactions that might cause the fire to reignite. These are primarily used for commercial cooking fires. Clean agent extinguishers, which release a gas that effectively extinguishes most types of fires and leaves no residue behind. Dry powder extinguishers are similar to dry chemical extinguishers, but they are only effective at putting out fires fueled by flammable metals (class D). Water mist extinguishers, which are a more environmentally friendly alternative to clean agent extinguishers. They are good for use on class A and class C fires. The most common type of fire extinguisher for home or office use is the multipurpose dry chemical extinguisher, which can be used on class A, B, and C fires (ordinary combustibles, flammable liquid fires, and electronic fires).

Clean the valve assembly with a soft cloth or brush. Take apart the valve assembly by unscrewing the operating levers, the siphon tube (which extends down into the cylinder), and the valve stem assembly (which connects the valve to the siphon tube). Wipe all of the disassembled parts thoroughly, using a dry soft-bristle brush or a soft, clean rag. Use an air or nitrogen duster to blow any dust or residue out of the valve. Take the opportunity to check the inner components for any signs of wear or damage, such as cuts or scratches on the O-ring or valve stem seating. If you have an older plastic valve stem, replace it with a metal one from your extinguisher’s manufacturer.

Reassemble the valve assembly and set it aside. Put all the parts of the valve assembly back together, including the down-tube and any other internal components. Put the reassembled valve assembly out of the way on a clean, dry surface. Tighten the valve stem in place with a wrench to ensure that the pressurizing gas doesn’t leak once the extinguisher is repressurized. You may wish to lay down a drop cloth to protect your work surface from any extinguishing agent that’s clinging to the internal parts of the valve assembly.

Remove any residual chemical agent from the cylinder. Look inside the cylinder to see if there are any traces of the extinguishing agent inside. If so, empty it out into an appropriate disposal container and set it aside so you can dispose of it properly later. The type of disposal container you need will depend on what kind of chemical is in the fire extinguisher, so check the disposal instructions in the safety data sheet (SDS) for your specific extinguishing agent. You can find an SDS for most products by searching online. The dry chemical found in most home fire extinguishers is generally considered non-toxic, so you may be able to dispose of it in your regular trash. Simply dump it out into the trash can. However, you should contact your local fire department to find out about local disposal regulations. You can also reuse the remaining chemical as long as it is in good condition and the right type for your extinguisher.

Inspect the cylinder following CGA Visual Inspection Standard C-6. To ensure that your fire extinguisher works correctly, you’ll need to do an internal inspection of the cylinder for corrosion, pitting, and other damage. To do this correctly, follow the procedures outlined in the Compressed Gas Association publication, CGA C-6: Standards for Visual Inspection of Steel Compressed Gas Cylinders. You can purchase CGA C-6 online from the CGA website. If you notice any corrosion inside the cylinder, you’ll need to replace it. Wash out any dirt or other foreign material with water and a gentle cleanser, then make sure your cylinder is thoroughly dry before you refill it.

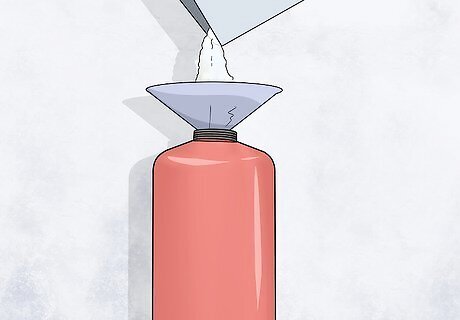

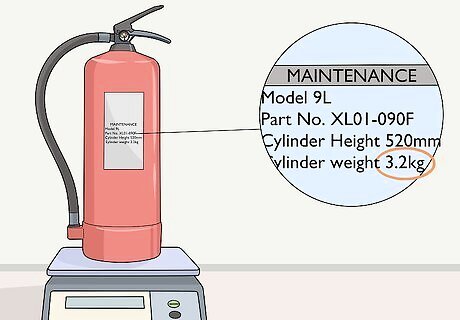

Fill the cylinder with the amount of chemical specified on the label. Use an accurate scale to measure out the correct amount of extinguishing agent based on the information on the label or in the owner’s manual. Depending on the type and model of your fire extinguisher, you may be able to simply insert a large funnel into the top of the extinguisher and pour in the extinguishing agent. Follow the instructions in your owner’s manual or on the label for the extinguishing agent. Use a plastic funnel rather than a metal one so that you don’t scratch the opening at the top of the cylinder. For some types of extinguishers, you may need to use a filling system, which is a device that automatically feeds the chemical into the cylinder through a hose. You can order a fire extinguisher filling system online or buy one from a local fire safety supply company. If you used a chemical reclamation system, you can refill the extinguisher with the extinguishing agent that you took out during the cleaning process. You may need to add additional, fresh chemical if there isn’t enough left over. Make sure you are not mixing different extinguishing agents!

Clean the extinguisher to remove any chemical residue. Use a small, stiff-bristle brush to clean the O-ring seat and threads on the cylinder collar. This is where the valve assembly attaches to the neck of the cylinder. Wipe down the rest of the cylinder with a clean cloth to remove any dust or splashes. If your manual instructs you to do so, brush the threads of the cylinder collar with a little silicone grease to help prevent corrosion and ensure the valve assembly can be easily removed and replaced.

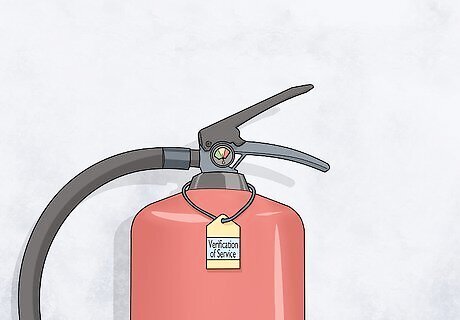

Reinstall the discharge valve. Put a “verification of service” tag on the cylinder collar, then put the discharge valve assembly back in place. Don’t put the hose back on yet. Be careful not to scratch the ring seating on the top of the cylinder when you reinstall the valve assembly, since scratches could cause the valve to leak. Take care not to over-tighten the valve assembly or strip the threads. On some models, you will hear a “click” when the valve is sufficiently tightened.

Re-Pressurizing the Extinguisher

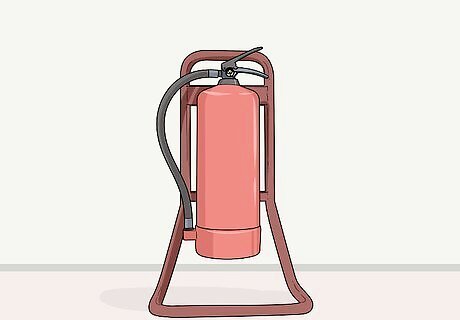

Secure the extinguisher in an upright position. Set the extinguisher upright on a stable, flat, surface. Ideally, you should secure it in place, e.g., by setting it on a portable fire extinguisher stand. You can also secure the fire extinguisher with a vice. You can purchase fire extinguisher stands online or from a fire safety supply store.

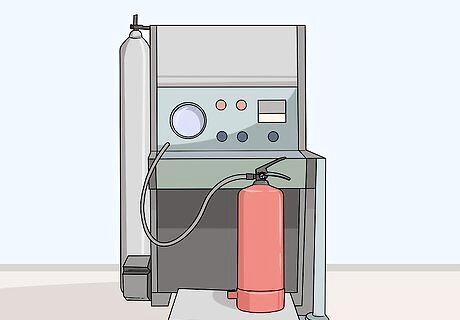

Attach the extinguisher valve to a pressurizing line. Place a pressurizing adapter in the discharge valve port, where the discharge hose is normally connected, and secure it in place. Attach the adapter to a line and connect it to the type of pressure source indicated in your owner’s manual. For example, most dry chemical extinguishers need to be pressurized with nitrogen. You’ll need a pressure vessel with a regulated pressure source. Don’t stand in front of the fire extinguisher’s pressure gauge while it’s attached to the pressure source, and do not allow the extinguisher to remain connected to the pressure source any longer than necessary. Too much pressure could cause the valve assembly to violently blow apart.

Pressurize the extinguisher with nitrogen to the psi specified in your manual. Set your pressure source to the psi indicated on the extinguisher label or in your owner’s manual. Make sure it’s preset to the right pressure setting or lower before you open the valve! Rotate the extinguisher operating valve lever until it’s in the “open” position, then begin pressurizing the extinguisher. Switch off the valve when you reach the desired pressure, then shut off and disconnect the nitrogen supply. For example, your model may specify a psi of 240. Use the gauge on the pressure source to make sure you have charged the extinguisher to the right pressure. Check that the gauge on the extinguisher is in the green once you’re done. If it’s not, check the gauge for damage and replace it if necessary.

Apply detecting fluid or soapy water to the collar and valve to check for leaks. It’s easiest to check for leaks in the fire extinguisher valve after it’s re-pressurized. Spray a little detecting fluid or soapy water on the collar and valve assembly as well as the pressure gauge and charging adapter port. If it fizzes or bubbles, that’s a sign that the extinguisher is leaking. Make sure all the parts that you sprayed with detecting fluid are thoroughly dry before you put the extinguisher back in service. Don’t remove the pressurizing adapter until after you’ve checked for leaks. If you find any leaks, you will need to replace the leaky part with an approved factory replacement. Check the gauge again 24-48 hours after you pressurize the extinguisher to make sure no pressure has been lost, since this could also indicate a leak.

Reconnect the hose and ring pin. Disconnect the extinguisher from the pressurizing adapter and put the discharge hose back in place. Coil the hose back up and replace it correctly on its rack. Mount the nozzle with the lever in the “closed” position. Slide the ring pin back in place and secure the safety seal. Make sure to record the recharge date on the service tag.

Weigh the fully assembled fire extinguisher. Set the fire extinguisher on a scale and make sure it meets the weight specifications on the label. If the weight is too low, the extinguisher may not be sufficiently filled. You can find the allowable weight range on the “Maintenance” section of the label.

Remount the extinguisher in its regular location. Put the extinguisher back in its regular stand, mounting bracket, or storage case. Make sure it is properly secured.

Maintaining a Refilled Extinguisher

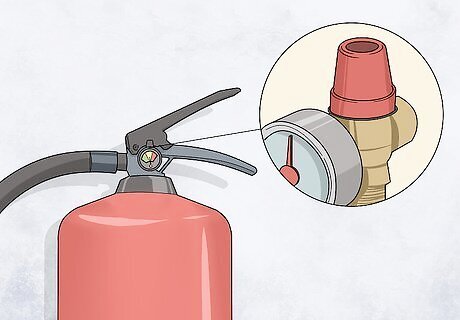

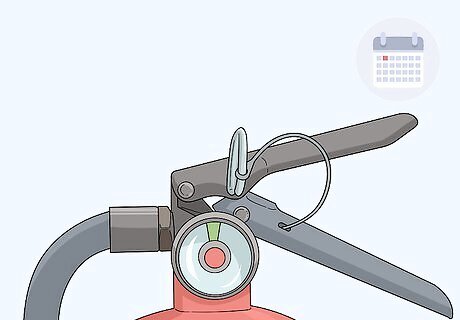

Check monthly to make sure the pressure gauge is in the green. The pressure gauge is located at the top of the extinguisher's head and points to its air pressure. If the needle falls anywhere beyond the green area noted on your extinguisher, hire a fire technician to inspect it or replace it with a new one. Some older fire extinguishers may not have a gauge. In this case, hire a fire technician to check the pressure once a month.

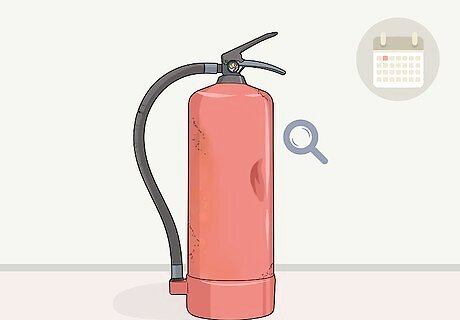

Inspect the extinguisher for damage once a month. Even if you're not refilling the extinguisher, checking for routine damage helps make sure that it's working properly. Look for any broken, cracked, or missing parts of the fire extinguisher and, if you notice extensive damage, discard it immediately. If you notice minor damage, hire a fire technician to determine whether you should throw the extinguisher away.

Hire a fire technician to inspect the extinguisher annually. Fire technicians will be able to spot small signs of damage that untrained eyes might not notice. Once a year, hire a fire technician for a routine inspection to make sure your extinguisher is still in working order. Check the label to find out if your extinguisher needs more frequent inspections or maintenance. Most fire extinguishers have a tag for the fire technician to sign and date after completing their inspection. If you're not sure when the extinguisher last had an inspection, check the tag. If the fire extinguisher doesn't have a tag and you can't remember when you last scheduled an inspection, contact a fire technician as soon as possible. Depending on the type of extinguisher you have, an annual inspection may cost less than $10 USD. However, many fire safety companies charge a significant service fee ($50 USD or more) if they have to travel to your location to inspect the extinguisher.

Replace your fire extinguisher instead if you notice extensive damage. Severely damaged fire extinguishers will not work correctly or protect you during a fire. If you notice any signs of serious damage, replace the fire extinguisher immediately.

Comments

0 comment