views

X

Research source

Taking Apart the Boiler

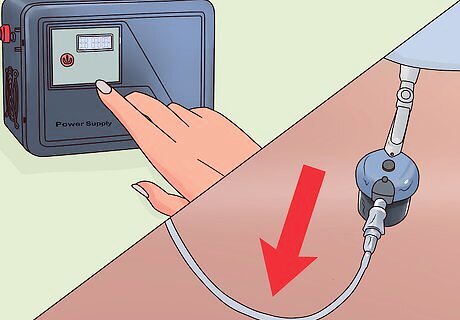

Turn off the electrical power supply and the fuel supply. The electrical power supply will often be a switch on a red switch plate that is located at the top of the basement stairs or near the boiler. The fuel shutoff valve is either located near the oil tank (for oil boilers) or incoming gas pipe (for gas boilers). You can also disconnect the power and fuel lines from the boiler. Place the end of the fuel line in a container to catch any fuel that may drip out of the line.

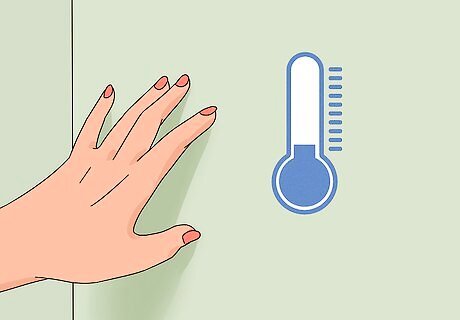

Let the boiler cool until it is cool to the touch. This is important to ensure your safety as you clean the boiler. Since it may take several hours to cool down, clean the boiler before heating season begins.

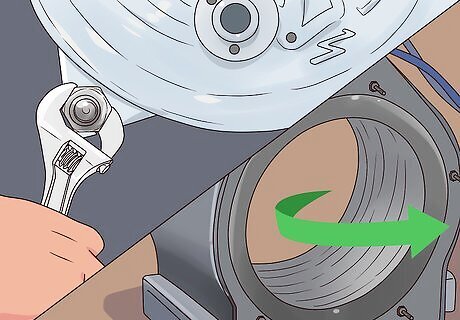

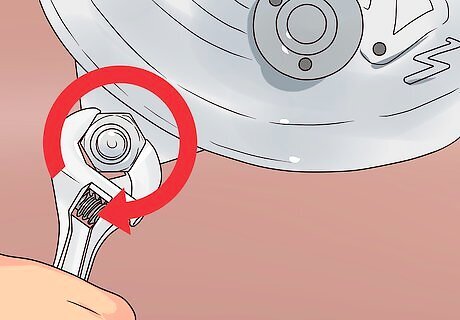

Remove the nut on the combustion chamber door and open the door. The combustion chamber door is located on the front of the boiler. You may need to use a wrench to remove the nut. Place the nut somewhere secure so that you can easily locate it later.

Cleaning and Reassembling the Boiler

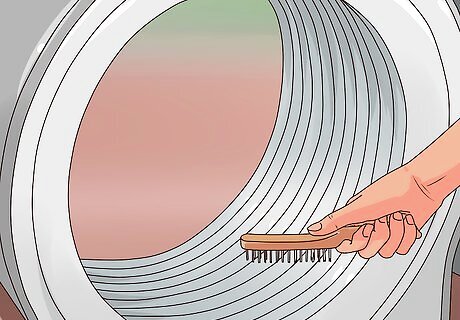

Scrape the soot from the combustion chamber walls with a wire brush. Excess soot buildup can cause the boiler combustion chamber walls to corrode. Once the walls have been scraped clean, remove the soot with an industrial shop vac. The combustion chamber is where the fuel mixes with air and is ignited to generate heat. Soot is a byproduct of this process. Hardware stores often offer industrial shop vacs for rent. They are also available from construction supply rental companies.

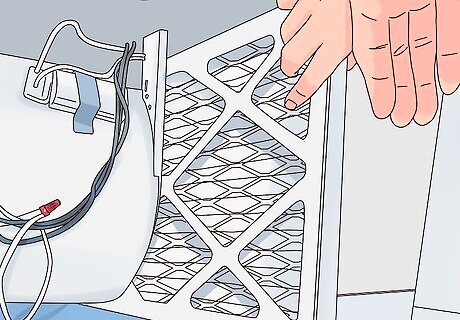

Change the air filter, if you have an oil-powered boiler. Close the oil valve, unscrew the oil filter, and replace it with a new one. The filter captures impurities that could clog the oil-burning nozzle and cause a misfire that shuts down the system. Air filters can be purchased online or at a hardware store that stocks HVAC supplies. Follow local hazardous-waste regulations when disposing of the old filter.

Close the combustion chamber door and replace the nut. Use a wrench to tighten the nut until it is firmly in place.

Reattach the power and fuel lines to the boiler if you disconnected them. Turn the electrical power and fuel supply back on. Leave the fuel valve open until the fuel starts flowing to allow any air trapped in the fuel line to escape. While the fuel valve is open, place a container under it to capture any excess fuel.

Maintaining the Boiler

Check the temperature and pressure readings regularly. Boilers typically have gauges that monitor the boiler water temperature, circulating pump temperature, and pressure. Refer to the owner’s manual to make sure they are within correct limits. This will help you catch any potential problems.

Lubricate the circulating pump periodically. The circulating pump is what moves the heated water from the boiler to the radiators, and is usually connected to a pipe near the boiler. Keeping it well-lubricated can prevent other system failures. Check the owner’s manual for guidance on how often to lubricate the circulating pump.

Check the water level in the expansion tank regularly. This is a small tank that protects the heating system from excessive pressure, and it should be about half full. If it is more than half full, open the expansion tank drain valve to return the tank to its correct level. If tank begins to refill after a couple of days, consult an HVAC professional. There might be a leak or the air tank may need to be recharged.

Hire a professional to clean the burners, coils, draft hood, and chimney. Soot will build up in these areas even if the boiler is properly maintained. They need to be cleaned by a certified HVAC professional for safety reasons.

Comments

0 comment