views

- Sheetrock is just a specific brand of drywall. All Sheetrock is drywall, but not all drywall is Sheetrock.

- Drywall comes in a variety of different thicknesses, dimensions, and styles.

- The only alternative to drywall is plaster, which is spread over horizontal boards, called lathe.

What is the difference between Sheetrock and drywall?

There is no functional difference between Sheetrock and drywall. Sheetrock is actually a brand of drywall. It’s made by the US Gypsum Company, and it’s a registered trademark, but there are other companies that make drywall and they’re all equally usable. In other words, all Sheetrock is drywall, but not all drywall is Sheetrock. The US Gypsum Company has added an inert ingredient or two to their drywall formula that allows them to trademark the “Sheetrock,” but their formula isn’t meaningfully different from other brands. It’s sort of like the difference between Kleenex and generic tissue paper. Sheetrock developed a reputation for being safer than generic brands because Chinese manufacturers used too much sulfur from 2000 to 2009 (which can cause health problems). Today, Sheetrock is no safer than any other high-quality drywall company’s product.

What is drywall?

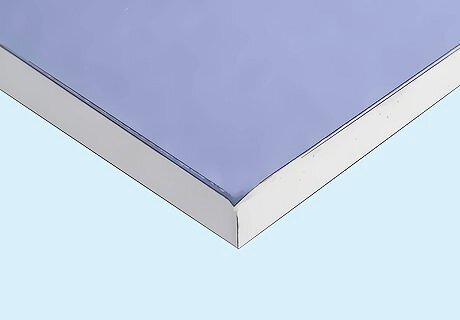

Drywall is a building material made of gypsum, wood, and pulp. Underneath those layers of paint on the wall you’re probably going to find drywall. It’s a rigid material that holds up well over time, but it’s not so hard that it’s difficult to hang or nail into wall joists. It’s made by crushing wood, paper pulp, and gypsum together in a thick layer. That layer is covered in paper and voila! You’ve got drywall. Drywall is also known as gypsum board, plasterboard, wallboard, and gypsum panel.

Drywall Dimensions

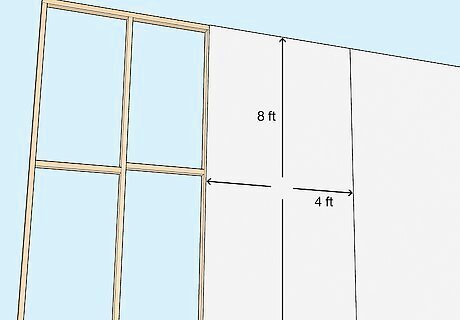

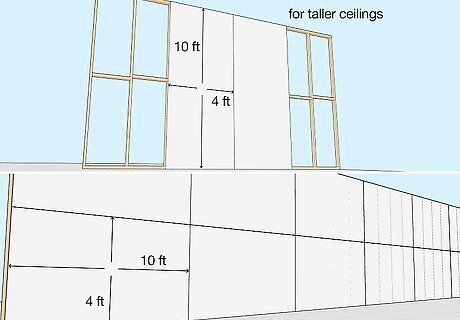

4 by 8 feet (1.2 by 2.4 m) This is the most popular size of drywall. It’s small enough that a normal worker can carry and install it regardless of how big they happen to be. The National Building Code also sets the standard ceiling height at 8 feet (2.4 m), so these drywall sheets can be hung in a single row.

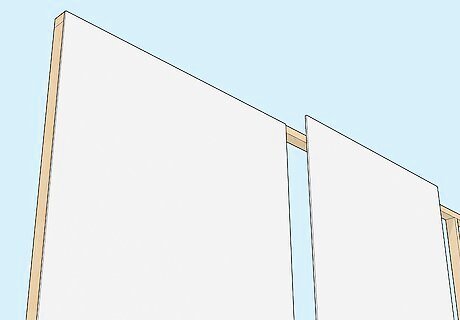

4 by 10 feet (1.2 by 3.0 m) Slightly bigger drywall is appropriate when you have taller ceilings, or if you’ve got longer walls and you want to minimize the number of seams. By stacking two sheets horizontally on top of one another, you can cover a longer wall with standard ceiling heights.

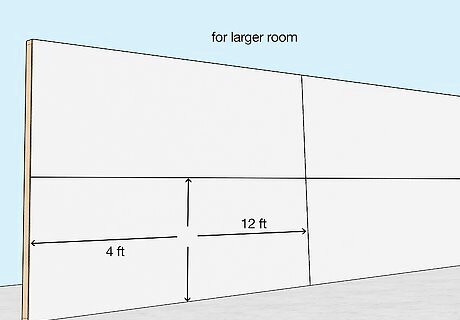

4 by 12 feet (1.2 by 3.7 m) This is the largest size available. It’s appropriate if you’ve got a ton of square footage to cover and your crew is large enough to maneuver and mount it. It’s also appropriate for lofts, vaulted ceilings, and other large rooms, since 12 feet (3.7 m) tends to be the maximum height of interior spaces.

Drywall Thicknesses

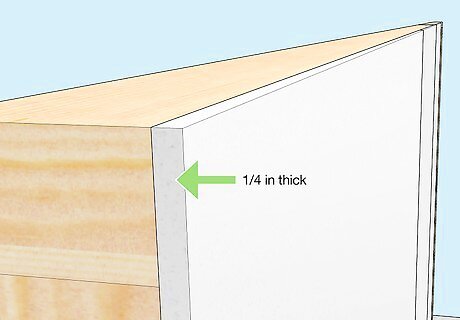

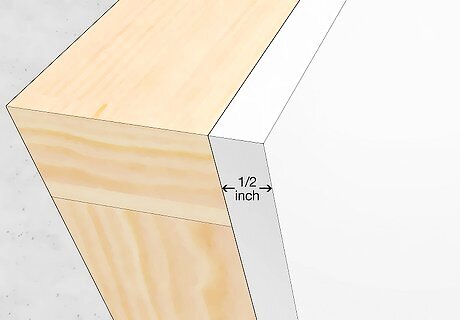

⁄4 inch (0.64 cm) This ultrathin drywall is typically only used as a skimming material to cut and install strange corners or cover up finished drywall to hide blemishes. It’s also ideal for curved walls, since it’s a lot easier to bend the thinner stuff without damaging it.

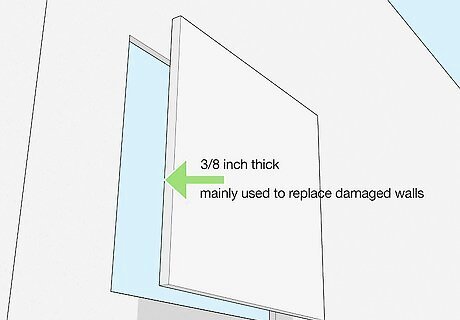

⁄8 inch (0.95 cm) This drywall is also mainly used to replace damaged walls. It’s a little easier to work with and cut, but thick enough that you can cover up the depth difference with joint compound.

⁄2 inch (1.3 cm) This is standard drywall size. It’s the most common kind of drywall you’ll find if you wander into a building supply store. It’s ideal for interior walls. There’s also a lightweight version that’s easier to work with if weight is a concern.

⁄8 inch (1.6 cm) This is the thickest type of drywall. It’s extremely unlikely to sag, but it’s exceptionally heavy. You typically only find this thickness on soundproofing or fire-resistant drywall.

Types of Drywall

Whiteboard This is what the average person pictures when they hear the word “drywall.” It’s the standard option for walls and ceilings. Unless you have specific needs, this is the right building material for you. Just FYI, all of the “color” boards are actually the color in their name. Whiteboard is white, greenboard is green, etc.

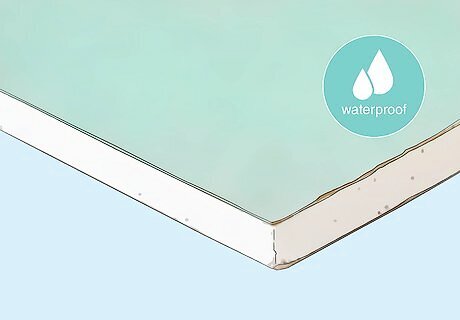

Greenboard Greenboard is water resistant. Normal whiteboard will eventually soften and degrade if it gets wet, but not greenboard. This makes it ideal for basements that may end up with moisture or water on occasion, or bathrooms that are going to steam up when you shower. Don’t use greenboard everywhere! It’s heavier and weaker than typical drywall, which doesn’t make it ideal for normal rooms.

Blueboard Blueboard is often not considered drywall because it’s used for modern plaster (more on that later), but it is a type of drywall. The blue paper that covers the gypsum is intentionally designed to be absorbent and porous, which makes it easier for plaster veneer to bond with the wall. Blueboard is used exclusively for plaster. The porous nature of the material means you can’t paint it.

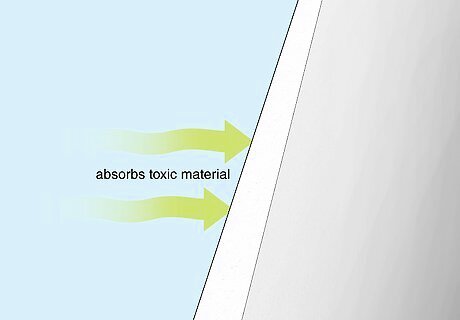

VOC-absorbing drywall This is a modern invention. It absorbs VOCs (volatile organic compounds), which are a toxic material found in paint, varnish, carpet, and lots of other household materials. In theory, it should help reduce pollutants in your home’s air. This VOC-absorbing quality of this material should work for up to 75 years.

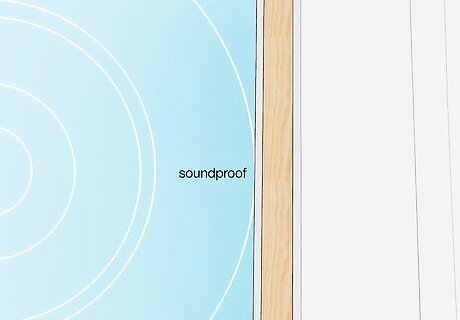

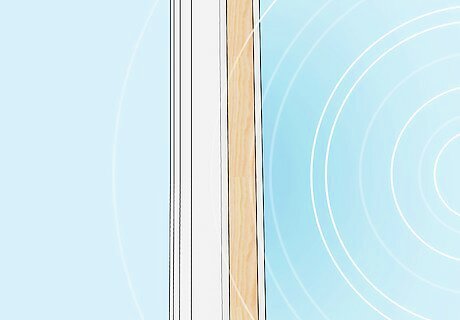

Acoustic drywall Acoustic drywall, or soundproofing drywall, is thicker and insulated. It’s extremely difficult to cut, but it really will keep sound out. If you’re setting up a home studio or you’re rehabbing a condo with shared walls, consider spending the extra money on some soundproofing boards.

Fire-resistant drywall Fire-resistant drywall contains calcium sulfate and water. When this drywall gets hot, it releases the water as a form of steam which helps to slow down flames or extinguish small fires. As a note, normal whiteboard drywall is non-combustible. It can burn, but it takes an extended exposure to fire.

Alternatives to Drywall

Plaster is the main alternative to drywall. You basically have two options when it comes to finishing interior walls: drywall or plaster. Before 1940, plaster and lathe was the most popular finishing option. Basically, a bunch of horizontal boards, called lathe, are installed on top of the studs. Then, plaster is spread over the lathe. Plaster is much more expensive than drywall, but it’s much harder and holds up better over time. Today, if you hire contractors to install plaster, they’ll hang blueboard instead of installing lathe since it’s much faster and more cost effective.

Comments

0 comment